Pemesinan presisi CNC lima sumbu - berdedikasi pada manufaktur terpadu permukaan kompleks dan komponen struktur tidak beraturan

- Gambaran Umum

- Produk Terkait

1、 Keunggulan layanan utama

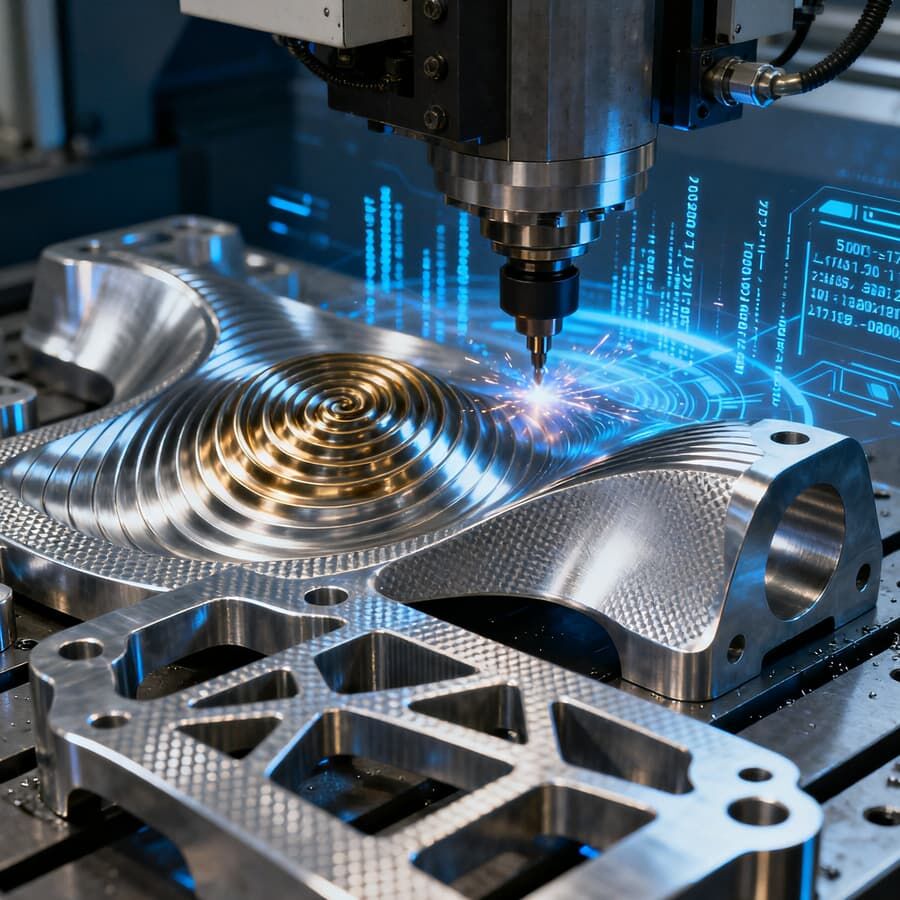

Pembentukan presisi permukaan kompleks, menembus keterbatasan dimensi pemesinan

Dengan mengandalkan teknologi lima sumbu hubungan (sumbu linier X/Y/Z + sumbu rotasi A/C), dapat dicapai pemrosesan "sudut ganda, tanpa sudut mati" yang mampu memahat akurat kontur kompleks seperti permukaan bola, heliks, dan permukaan bebas. Kesalahan kontur permukaan adalah ≤± 0,005 mm, dan kehalusan permukaan dapat mencapai Ra ≤ 0,4 μm. Dibandingkan dengan pemrosesan multi tahap konvensional, tidak perlu menyesuaikan posisi benda kerja berulang kali, sehingga menghindari kesalahan posisi kumulatif, sangat cocok untuk komponen seperti bilah mesin pesawat terbang dan sendi buatan medis yang memerlukan kecocokan permukaan sangat tinggi.

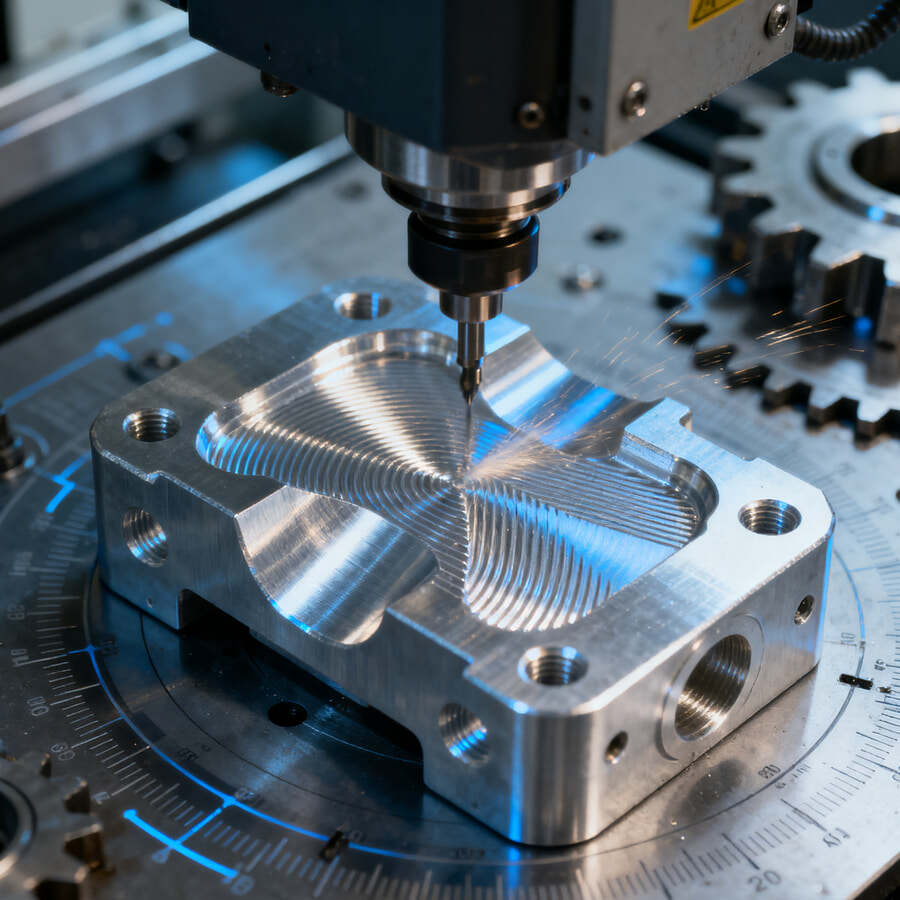

Produksi terpadu struktur tidak beraturan, mengurangi proses dan meningkatkan efisiensi

Untuk komponen struktural berbentuk khusus dengan lubang, kontur tidak beraturan, dan permukaan saling berpotongan (seperti lengan robot dan braket berbentuk khusus pada peralatan energi baru), dapat mewujudkan "pemasangan sekali, pemrosesan struktur penuh", mengintegrasikan berbagai proses seperti frais, bor, dan pemotongan chamfer, mengurangi jumlah proses lebih dari 40% dan memperpendek siklus pemrosesan 30%-50% dibandingkan proses konvensional. Pada saat yang sama, menghindari kesalahan penyetelan struktur akibat pemasangan berkali-kali, serta memastikan parameter krusial seperti koaksialitas lubang dan kesejajaran kontur permukaan pada bagian tidak beraturan memenuhi standar desain.

Kompatibilitas bahan yang luas, mampu menyeimbangkan pemrosesan bahan keras dan bahan yang mudah berubah bentuk

Pengolahan material keras: Untuk material berkekuatan tinggi seperti paduan titanium, paduan tahan panas, karbida tungsten, dll. (dengan kekerasan HRC50 atau lebih), dilengkapi dengan spindle berkekuatan tinggi (torsi maksimum 80N·m) dan pahat paduan keras berbutir ultra halus, dikombinasikan dengan sistem pendingin bertekanan tinggi (tekanan pendingin 100bar), untuk mengatasi permasalahan pahat mudah patah dan efisiensi rendah dalam pengolahan material keras. Dapat memproses secara stabil komponen struktur tidak beraturan berkekuatan tinggi di bidang kedirgantaraan;

Pengolahan material yang mudah terdistorsi: Untuk material seperti paduan aluminium dan plastik teknik (seperti PEEK, POM) yang cenderung mengalami distorsi termal, digunakan teknologi pemotongan suhu rendah dan perlengkapan fleksibel untuk mengurangi tegangan termal selama pengolahan, menghindari pelengkungan permukaan lengkung kompleks dan penyimpangan dimensi struktur tidak beraturan, serta menyesuaikan diri pada penggunaan seperti rumah perangkat elektronik presisi.

Kualitas seluruh proses dapat dikontrol, memastikan konsistensi komponen kompleks

Membangun sistem kontrol loop tertutup "desain-pemrosesan-pengujian": memprediksi risiko tabrakan melalui simulasi jalur pemesinan permukaan kompleks dengan perangkat lunak CAD/CAM sebelum pemrosesan; Pemantauan beban spindle dan suhu pemotongan secara real-time selama proses, kompensasi otomatis untuk keausan alat; Setelah proses selesai, menggunakan mesin ukur koordinat tiga dimensi (dengan akurasi ± 0,001 mm) dan pemindai cahaya biru (efisiensi pemeriksaan ukuran penuh meningkat 60%) untuk melakukan inspeksi menyeluruh terhadap permukaan lengkung kompleks dan struktur tidak beraturan. Data inspeksi disimpan untuk setiap batch komponen guna memastikan konsistensi dalam produksi massal.

2、 Bidang aplikasi utama

Bidang kedirgantaraan

Sudut baling-baling mesin pesawat terbang yang disesuaikan (permukaan kompleks + material paduan suhu tinggi), rangka badan pesawat tidak beraturan (struktur segi banyak bertingkat), reflektor antena satelit (permukaan parabola presisi tinggi), pengolahan lima sumbu dapat memenuhi persyaratan ketat industri kedirgantaraan akan komponen yang ringan, kuat, dan presisi tinggi, serta mampu beradaptasi dengan lingkungan penerbangan ekstrem.

Bidang peralatan medis

Menghasilkan sendi buatan (terbuat dari material paduan titanium + permukaan lengkung kompleks yang menyesuaikan bentuk tubuh manusia), end-effector robot bedah (struktur pengunci berbentuk khusus), dan kamar presisi untuk instrumen diagnostik (struktur berongga), dengan tingkat akurasi pengolahan yang memenuhi standar medis (seperti kekasaran permukaan Ra ≤ 0,2 μm untuk sendi buatan), memastikan keamanan dan adaptabilitas peralatan.

Sektor Energi Baru

Memproses shell tidak beraturan pada gearbox turbin angin (struktur lubang multi sumbu yang tidak sejajar), struktur penopang kompleks berbahan aluminium untuk sistem pelacakan fotovoltaik, serta pembawa elektroda presisi tinggi pada peralatan penyimpanan energi (struktur konduktif tidak beraturan), dimana pengolahan lima sumbu yang sangat stabil dapat meningkatkan efisiensi operasional peralatan energi baru serta mampu beradaptasi dengan kondisi kerja luar ruangan yang kompleks.

Bidang manufaktur otomotif premium

Komponen tutup ujung motor kendaraan energi baru yang dibuat menyerupai bentuk khusus (struktur kompleks dengan saluran pendinginan terintegrasi), komponen rangka mobil balap berbahan ringan berbahan komposit serat karbon+permukaan lengkung kompleks), serta rumah LiDAR untuk sistem berkendara otomatis (jendela berbentuk sferis presisi tinggi), mampu menyeimbangkan kebutuhan kekuatan, bobot ringan, dan ketepatan perakitan pada komponen kendaraan.

Bidang otomasi industri

Lengan robot produksi yang berbentuk articulated (permukaan kompleks dengan penghubung multi sumbu), blok presisi berbentuk fixture (kontur tidak beraturan), sistem transmisi lini produksi otomatis dengan roller berbentuk khusus (struktur komposit karet tahan aus + logam), mesin lima sumbu dapat memastikan akurasi gerakan dan stabilitas peralatan otomatis, serta meningkatkan efisiensi produksi.

3. Dukungan teknis inti

Sistem CNC lima sumbu kelas atas

Dilengkapi dengan sistem CNC lima sumbu Siemens 840D SL dan Fanuc 31i-B, mendukung fungsi interpolasi kurva NURBS dan dapat memproses secara akurat lintasan pemesinan permukaan kompleks dengan ketelitian kontrol 0,1 μm. Dilengkapi secara bersamaan dengan fungsi kompensasi ketelitian dinamis (seperti kompensasi kesalahan panas, kompensasi kesalahan geometris), melakukan koreksi real-time terhadap deviasi pemesinan, memastikan stabilitas ketelitian dalam jangka panjang pemesinan bagian kompleks.

Struktur mesin perkakas dengan kekakuan tinggi

Rangka mesin terbuat dari besi cor yang telah melalui tiga kali proses penuaan untuk menghilangkan tegangan internal dan mengurangi getaran selama pemotongan; Mengadopsi struktur meja putar ganda bertipe buaian (rentang putaran sumbu A -120 °~120 °, rentang putaran sumbu C 0 °~360 °), akurasi posisi meja putar adalah ± 0,001 °, memberikan dukungan stabil untuk pemrosesan sudut ganda pada permukaan kompleks dan pemrosesan berbagai sisi pada struktur tidak beraturan.

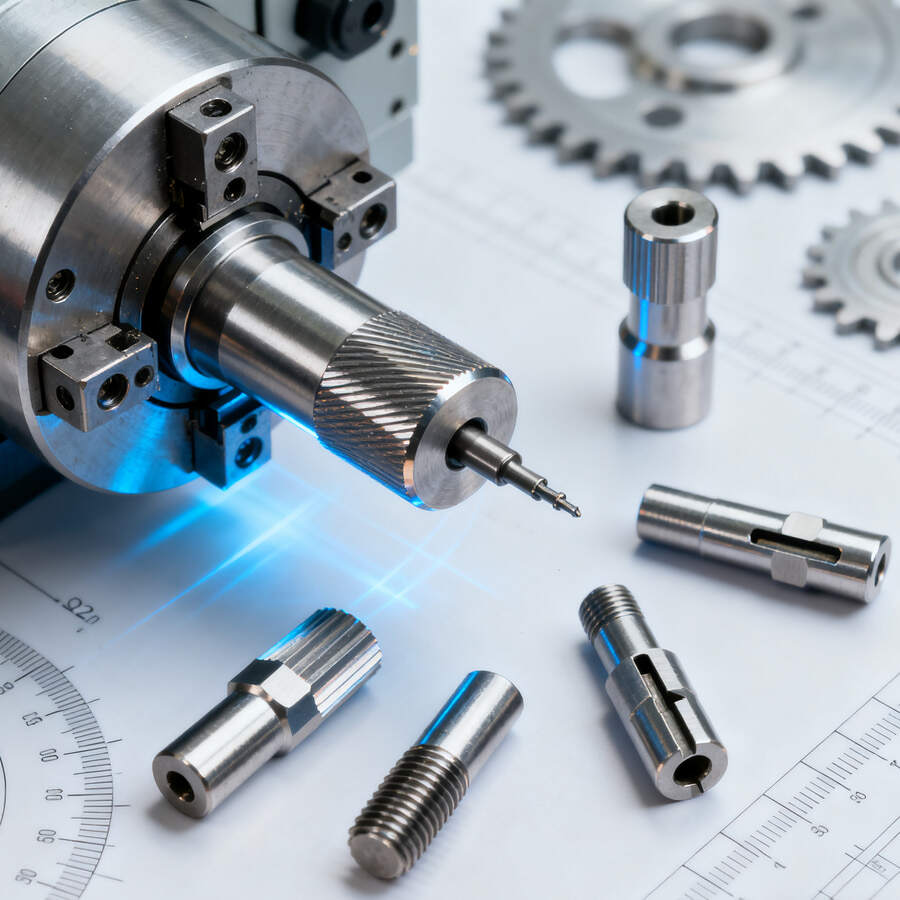

Alat pemotong dan proses pemotongan khusus

Peralatan: Dilengkapi dengan ball end milling cutters dan rounded corner milling cutters (dengan ketelitian tepi potong ± 0,002 mm) untuk permukaan kompleks, serta alat potong cetakan dan non-standar untuk struktur tidak beraturan demi meningkatkan efisiensi pemrosesan dan kualitas permukaan;

Proses: Teknologi frais kecepatan tinggi (kecepatan maksimum spindle 18000rpm) digunakan untuk memachining permukaan lengkung kompleks dari paduan aluminium, dengan kekasaran permukaan hingga Ra ≤ 0,4 μm; Mengadopsi teknologi frais berlapis untuk memproses rongga dalam tidak beraturan pada baja tahan karat, menghindari getaran alat dan memastikan keteraturan dinding rongga.

Teknologi integrasi digital

Perkenalkan platform terpadu CAD/CAM/CAE: menyelesaikan pemodelan 3D permukaan kompleks dan struktur tidak beraturan melalui perangkat lunak seperti SolidWorks dan UG; Menghasilkan lintasan pemesinan lima sumbu menggunakan Mastercam dan PowerMILL, melakukan simulasi proses pemesinan serta mengoptimalkan parameter-parameter; Dikombinasikan dengan sistem eksekusi produksi MES, mewujudkan pelacakan kemajuan pesanan, pemantauan status peralatan, serta keterlacakan data pengujian, menciptakan proses manufaktur terpadu yang "digital dan transparan".

4. Pertanyaan yang Sering Diajukan (FAQ)

P: Apa kisaran ukuran maksimum untuk permukaan lengkung kompleks dan komponen struktur tidak beraturan yang dapat dikerjakan? Apakah dapat mendukung pengolahan bagian yang sangat besar?

J: Kisaran ukuran pengolahan konvensional adalah panjang 1200mm, lebar 800mm, dan tinggi 600mm; bagian yang sangat besar (seperti komponen berbentuk turbin angin dengan panjang lebih dari 2000mm) dapat dicapai melalui teknologi "pengolahan tersegmentasi + penyambungan presisi", dan perlu menyediakan model 3D terlebih dahulu. Insinyur teknis akan mengevaluasi kelayakpakaian struktur dan menyusun rencana eksklusif.

P: Apakah ada perbedaan dalam ketelitian pemesinan antara permukaan kompleks dan komponen struktur tidak beraturan? Apa saja indikator ketelitian spesifiknya?

A: Karena karakteristik struktural yang berbeda, terdapat sedikit perbedaan pada indikator akurasi: kesalahan kontur permukaan kompleks adalah ≤± 0,005 mm, dan kekasaran permukaan Ra adalah ≤ 0,4 μm; Konsentrisitas posisi lubang komponen struktur tidak beraturan adalah ≤± 0,003 mm, dan kesejajaran kontur permukaan adalah ≤± 0,004 mm. Parameter presisi tersebut dapat dioptimalkan lebih lanjut sesuai dengan tujuan spesifik dari komponen.

P: Informasi teknis apa saja yang diperlukan untuk memesan bagian kompleks secara khusus? Jika terdapat kesulitan dalam proses desain, apakah Anda dapat membantu mengoptimalkannya?

A: Sarankan menyediakan model 3D detail (dalam format STEP, IGS, atau X_T) dan gambar teknik 2D (yang menunjukkan toleransi, material, dan persyaratan perlakuan permukaan); Jika terdapat kesulitan dalam proses pengerjaan pada desain (seperti permukaan terlalu curam atau dinding tipis pada struktur tidak beraturan), engineer kami dapat memberikan saran optimasi DFM (Design for Manufacturability), menyesuaikan parameter struktural untuk meningkatkan kelayakpakerjaan dan efisiensi proses, tanpa biaya tambahan.

P: Berapa lama siklus pengiriman untuk pengerjaan permukaan kompleks dan bagian tidak beraturan? Apakah pesanan mendesak dapat dipercepat?

A: Pesanan partai kecil berkala (1-20 pcs): bagian berbentuk lengkung sederhana dan kompleks dikirim dalam waktu 7-10 hari, sedangkan bagian struktural tidak beraturan kompleks dikirim dalam waktu 10-15 hari; Pesanan skala besar (lebih dari 100 pcs) dapat diproduksi secara paralel dengan beberapa mesin untuk memperpendek waktu pemesanan, dan waktu pengiriman spesifik dapat dinegosiasikan. Pesanan darurat (seperti suku cadang perbaikan aerospace) dapat dilayani secara dipercepat dalam 72 jam, namun diperlukan komunikasi sebelumnya untuk memastikan kapasitas produksi.

Q: Apakah kami dapat menyediakan layanan produksi percobaan sampel untuk komponen kompleks? Massal produksi setelah sampel memenuhi syarat?

A: Mendukung layanan produksi percobaan sampel! Untuk permukaan lengkung kompleks dan komponen struktur tidak beraturan, dapat dibuat terlebih dahulu 1-3 buah sampel. Setelah pelanggan mengonfirmasi akurasi, tampilan, dan kesesuaian perakitan sampel tersebut, produksi massal dapat dimulai. Siklus produksi percobaan sampel 2-3 hari lebih singkat dibandingkan pesanan reguler. Selama proses produksi percobaan, parameter pemrosesan dapat disesuaikan berdasarkan umpan balik pelanggan untuk memastikan produk akhir sesuai dengan harapan.

| Pengolahan | Layanan Pemesinan CNC: CNC Milling, CNC Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, EDM, Pemesinan 3-Axis, 4-Axis, 5-Axis, Pemesinan dengan Mesin Swiss; Layanan Pemesinan Komprehensif: Metalurgi Serbuk, Fabrikasi Lembaran Logam, Stamping, Die Casting, 3D Printing, Injection Molding, Prototipe Cepat, Cetakan, dll.; Pemesinan Multi-Proses |

| Layanan Perakitan | Pengencangan & Penyambungan, Perakitan Komponen, Perakitan Penuh, Pengemasan & Pemberian Label |

| Bahan | Aluminium: seri 2000, seri 6000, 7075, 5052, dll. |

| Baja tahan karat: sus303, sus304, ss316, ss316l, 17-4ph, dll. | |

| Baja: 1214l/1215/1045/4140/scm440/40crmo, dll. | |

| Kuningan: 260, c360, h59, h60, h62, h63, h65, h68, h70, perunggu, tembaga | |

| Plastik: asetat/pom/pa/nylon/pc/pmma/pvc/pu/akrilik/abs/ptfe/peek dll. | |

| Toleransi Presisi | ±0,001mm~±0,005mm Produk tertentu dapat memenuhi persyaratan pelanggan. |

| Kekasaran permukaan | Min ra 0,1 ~ 3,2 |

| Perlakuan Permukaan | Anodizing, Bead Blasting, Silk Screen, Pelapisan PVD, Pelapisan Seng/Nikel/Krom/Titanium, Brushing, Painting, Powder Coating |

| Dilapisi, Sandblasting , Passivasi, Elektroforesis, Pengilapan Elektrolitik, Knurl, Laser/Etch/Engrave dll. | |

| Volume produksi | Volume Rendah hingga Sedang, Prototipe, dan Produksi Batch |

| Metode pengolahan | Khusus Sesuai Gambar CAD yang Disediakan |

| Waktu Tunggu | Waktu Pemesanan Singkat, Biasanya 1-4 Minggu |

| Kontrol Kualitas | Proses Jaminan dan Pemeriksaan Kualitas yang Ketat |

| Kemasan | Pengepakan Aman untuk Mencegah Kerusakan Selama Pengiriman |

| Sertifikat | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE dll. |

| pesanan Minimum 1 Buah | Kemampuan untuk Menyediakan Sampel Sebelum Produksi Massal |