- Oversikt

- Relaterte produkter

I. Kjerne Tjeneste Fordeler

- Oppnå enkelt komplekse strukturer, og bryt gjennom begrensningene ved tradisjonelle prosesser: Støtter integrert utskrift av komplekse design som hule strukturer, gittermønstre, spesialformede overflater og interne kanaler for væskestrøm, noe som eliminerer behovet for demontering og montering av deler, og forbedrer strukturell integritet med over 80 %. For eksempel kan topologisk optimaliserte luftfartøyskroker og forminnsettinger med interne kjølekanaler skrives direkte ut, med strukturelle toleranser innenfor ±0,1 mm – noe som er vanskelig å oppnå med tradisjonelle prosesser.

- Effektiv og fleksibel produksjon i små serier, som reduserer syklustidene betydelig: Produksjon i små serier på 1–500 enheter kan gjennomføres uten opprettelse av støpeforme, noe som forkorter produksjonsperioder med 60–70 % sammenlignet med tradisjonell injeksjonsstøping/støping (levering fra design til ferdig produkt på så kort tid som 24 timer). Enhetskostnadene justeres fleksibelt basert på seriestørrelse og sparer 50–80 % av den første investeringen ved liten serieproduksjon sammenlignet med formframstilling. Denne løsningen er ideell for produktutvikling, prøveproduksjon og skreddersydde ordre.

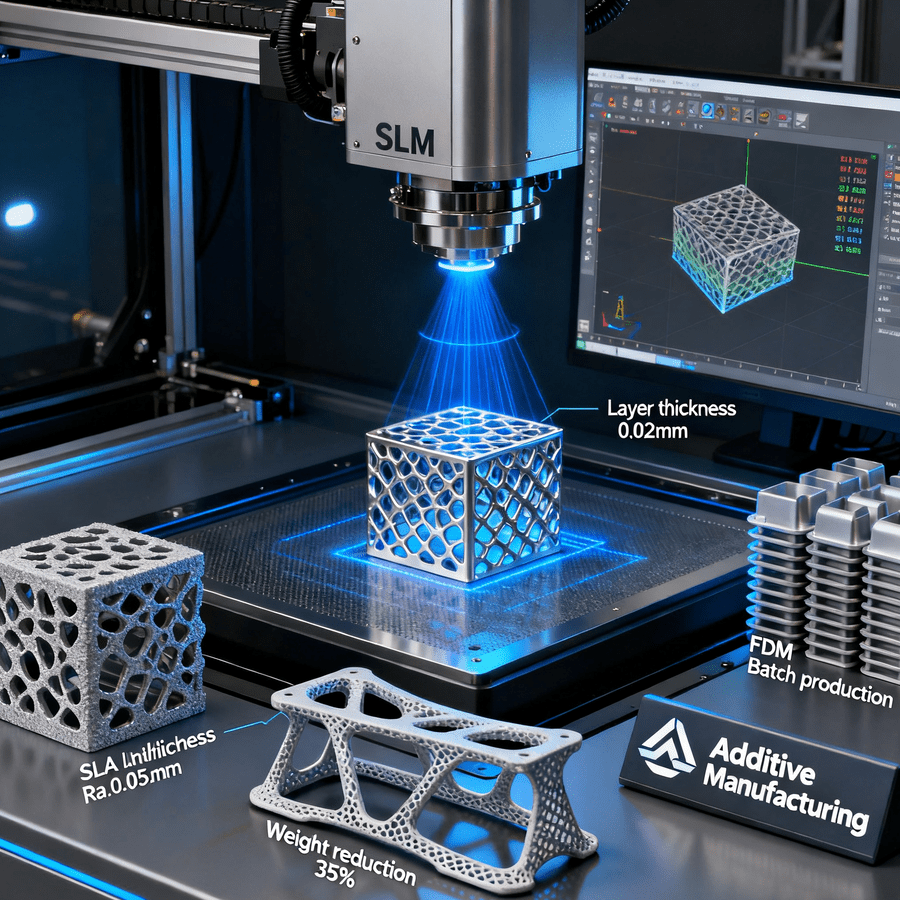

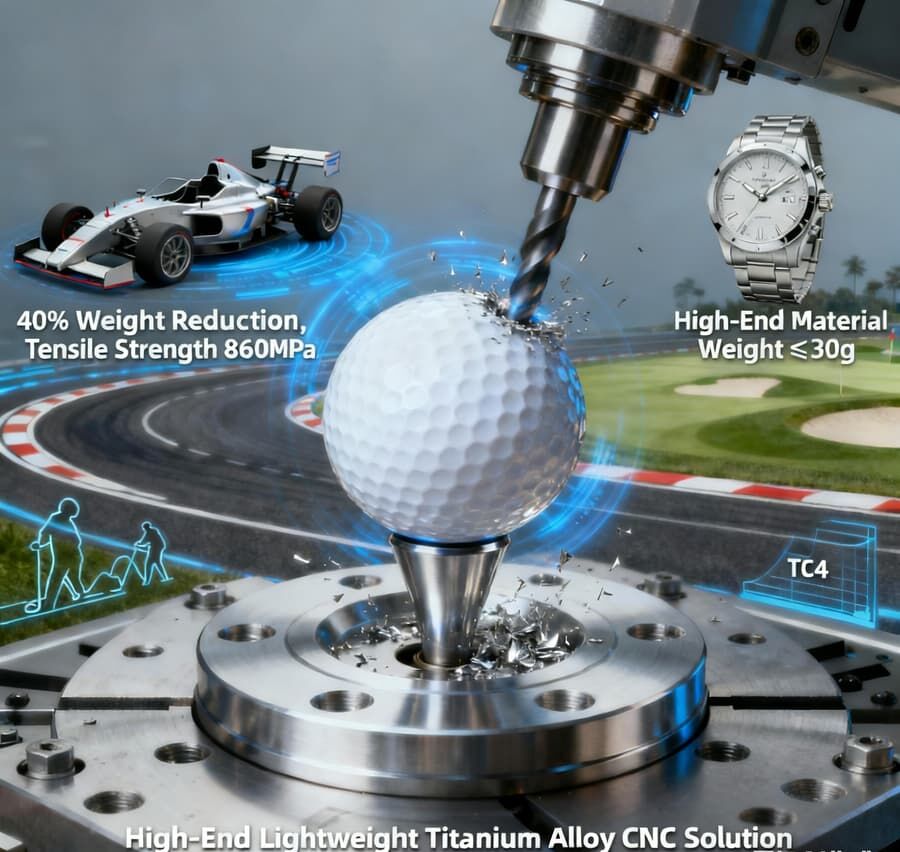

- Kompatibel med flere materialer og prosesser for å oppfylle mangfoldige ytelseskrav: Vi tilbyr dominerende prosesser som FDM (fused deposition modeling), SLA (stereolithography) og SLM (selective laser melting), og er kompatibel med over 20 materialer, inkludert ABS, PLA, lysfølsom harpiks, nylon, titanlegering og aluminiumslegering. Vi anbefaler kombinasjoner av prosess og materiale basert på delenes bruksområde (for eksempel høy temperaturmotstand, høy fasthet og god lysgjennomtrengelighet). For eksempel krever SLM-deler i titanlegering en strekkfasthet på ≥900 MPa, mens SLA-deler i lysfølsom harpiks krever en overflateruhet på Ra ≤0,05 μm.

- Fullkjedestøtte fra design til produksjon for å senke R&D-hindre: Vi har et profesjonelt designteam og tilbyr tjenester som reparasjon av 3D-modeller, topologioptimering og prosessfeilbarhetsanalyse. Basert på kundens oppgitte 2D-tegninger eller foreløpige 3D-modeller, optimaliserer vi strukturen for å forbedre utskriftseffektivitet og delytelse. Simulering før utskriften hjelper med å unngå feil som krumning og lagdelaminering, noe som resulterer i en første-gangs-utskriftssuksessrate på over 95 %.

II. Kjerne Anvendelse Områder

(I) Produktutvikling og prototyping

- Prototyper for industrielt design: Hurtigutskriving av prototyper av konsumentelektronikk (som telefondeksler og hodetelefoner) og hJEM husholdningsapparater. SLA-prosessen gir svært realistiske overflateeffekter (som matt og glansfinish), noe som gjør at designere kan fullføre flere versjonsverifikasjoner innen 3–5 dager, og dermed akselerere produktiterasjon.

- Funksjonelle testprototyper: Tull funksjonelle prototyper av bilkomponenter (som sensorholder) og mekaniske strukturkomponenter. Ved bruk av nylon (støtdemping ≥ 50 kJ/m²) for montering og ytelsestesting, kan designfeil oppdages tidlig og risikoen for feil ved formåpning reduseres.

(II) Luft- og romfart og medisin

- Lettvektskomponenter for luft- og romfart: SLM-prosesser av titanlegeringskomponenter og aluminiumslegeringsmotor-deler til luft- og romfart. Gitterstrukturdesign reduserer vekten med 30–40 % samtidig som det sikrer tilstrekkelig fasthet, og dermed oppfylles kravene til lettvikt for romfartøy.

- Skreddersydde medisinske produkter: 3D-utskrift av personlige ortopediske guider (laget av harpiks, med en nøyaktighet på ±0,05 mm) og tannimplantatommodeller, tilpasset pasientens anatomi for økt kirurgisk presisjon; utskrift av hjelpemidler for rehabilitering (som skreddersydde håndstøtter) som kombinerer komfort og funksjonalitet.

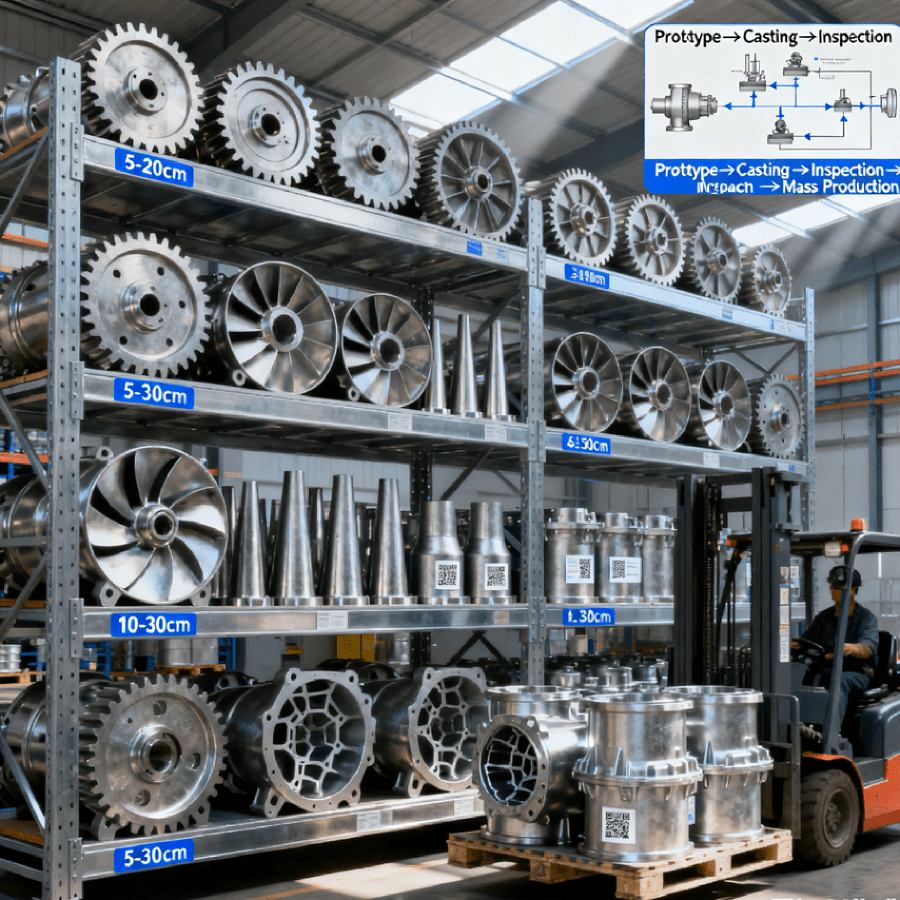

(III) Industriell produksjon og former

- Småserie egendefinerte deler: Utskrift av små serier med ikke-standardtilbehør (som gripehender og forbindelsesakser) for automatiseringsutstyr og robotindustrier. Det kreves ingen malframstilling, og levering fullføres innen 7–10 dager, noe som løser problemer med lange produksjonsperioder og høye kostnader knyttet til tradisjonelle småseriesproduksjonsprosesser.

- Raske former og verktøy: 3D-utskrift av forminnsettinger og sveisevorster i harpiks. Formene kan produsere 100–500 deler ved injeksjonsforming, med en posisjoneringsnøyaktighet på ±0,1 mm. Dette reduserer produksjonsperioder med 50 % og kostnader med 40 % sammenlignet med tradisjonelle metallformer/verktøy.

(IV) Kultur- og kreativindustrier og forbrukersektor

- Tilpassede kulturelle og kreative produkter: Skriv ut personlig figuriner, kunstornamenter og tilpassede gaver. Støtter fargeutskrift og flermaterialsammenføyning, og kan reprodusere intrikate detaljer (som hår og relieffteksturer), og oppfyller «småserielle, personlige» behov for kulturelle og kreative produkter.

- Tilbehør til bærbare enheter: Skriv ut tilpassede stropper og kabinetter til smarte bærbare enheter. Laget av fleksibelt harpiks eller nylon, kombinerer de lettvikt og komfort, og tillater rask justering av design basert på brukerbehov.

III. Kjernteknologisk støtte

- Flere prosesser, høypresisjonsutstyrscluster: Utstyrt med industristandard FDM-skrivere (som Ultimaker S5, med en trykknøyaktighet på ±0,05 mm), SLA (Solid Light-Stage Lamination)-skrivere (som Formlabs Form 3+, med lagtykkelse på 0,025 mm) og SLM (Structure Layer Metallization)-skrivere (som EOS M290, med posisjoneringsnøyaktighet på ±0,02 mm). Disse skriverne dekker et bredt spekter av materialer og presisjonskrav, og kan produsere store deler opp til 1,2 m × 1,2 m × 1,2 m.

- Design- og simuleringsteknologi: Vi bruker Autodesk Fusion 360 og Magics for 3D-modellering og skiving, samt ANSYS for termisk spenningssimulering under printprosessen for å forutsi deformasjonstendenser i deler og justere skiveparametere. Vi benytter optimaliseringsalgoritmer for støttekonstruksjoner ved komplekse strukturer for å redusere mengden støttemateriale og etterbehandlingsarbeid.

- Materiale R&D og kvalitetskontroll: Vi samarbeider med anerkjente innenlandske og internasjonale materialeprodusenter for å sikre stabile materialegenskaper (f.eks. nylon bruddforlengelse ≥ 25 %, titanlegeringshardhet ≥ HRC30). Kvalitetsinspeksjon benytter blålys-skannere (nøyaktighet ±0,03 mm), strekktester og hardhetstester for å fullstendig inspisere delers dimensjoner og mekaniske egenskaper, og dermed sikre at de oppfyller kundens krav.

- Digital produksjonsstyring: Vi implementerer et MES-system som muliggjør sanntidsoppsporing av ordrefremdrift, overvåking av utstyrsstatus og sporbarhet av trykkparametere. Kunder kan se ordrefremdrift og inspeksjonsrapporter online. Vi etablerer også standardiserte etterbehandlingsprosesser (som rengjøring, herding, polering og farging) for å sikre konsekvent delutseende og ytelse.

IV. Vanlige spørsmål (FAQ)

- Spørsmål: Hva er forskjellene i bruksområdene for ulike 3D-printprosesser? Hvordan velger jeg en? Svar: FDM er egnet for lavkostnads, slitesterke plastdeler (som f.eks. verktøy og fixturer); SLA er egnet for høypresisjons, glatte overflater i harpiksdeler (som f.eks. eksterne prototyper); og SLM er egnet for sterke metalldeler (som f.eks. fly- og romfartsdelar). Vårt prosesslag vil anbefale den optimale løsningen basert på delens materiale, presisjons- og styrkekrav.

- Spørsmål: Hvor nøyaktige kan 3D-printede deler være? Hva er overflateryheten?

Svar: Presisjon for plastdeler er ±0,05–±0,1 mm, og presisjon for metalldeler er ±0,02–±0,05 mm. Overflateryhet for SLA-harpiksdeler er Ra ≤ 0,05 μm, for FDM-plastdeler er Ra ≤ 3,2 μm (kan reduseres til Ra ≤ 1,6 μm ved etterbehandling), og for SLM-metalldeler er Ra ≤ 6,3 μm (kan reduseres til Ra ≤ 1,6 μm etter polering).

- Spørsmål: Hva er minimumsordre for småserietilvirkning? Hva er maksimal størrelse for utskrift? Svar: Det finnes ingen streng minimumsordre, og vi godtar tilpassede ordre på kun ett stykk. Maksimale byggemål: 1,2 m × 1,2 m × 1,2 m for FDM, 0,3 m × 0,3 m × 0,3 m for SLA, og 0,25 m × 0,25 m × 0,3 m for SLM. For ekstra store deler kan vi bruke segmentert utskrift med presis montering.

- Spørsmål: Hva er gjennomføringstiden fra designfiler til ferdig produkt? Kan dere levere nødtjeneste?

- Svar: Enkle deler kan leveres innen 24–48 timer, mens komplekse deler eller små serier (10–50 stk) kan leveres innen 3–7 dager. Vi godtar akuttprioriterte ordre med expediert levering innen 12 timer via prioritering (avhengig av delens kompleksitet).

- Q: Hvordan sammenlignes levetiden for 3D-printede deler med deler produsert ved hjelp av tradisjonelle metoder? A: Under samme materiale- og driftsbetingelser er levetiden for 3D-printede deler sammenlignbar med den for tradisjonelle prosesser. Levetiden for noen topologisk optimaliserte deler (som gitterstrukturdelar) kan økes med 15–20 % på grunn av mer jevn spenningsfordeling. De mekaniske egenskapene og levetiden for metalldele kan ytterligere forbedres gjennom varmebehandling (som herding og kvensjing).