- Oversikt

- Relaterte produkter

I. Kjerne Tjeneste Fordeler

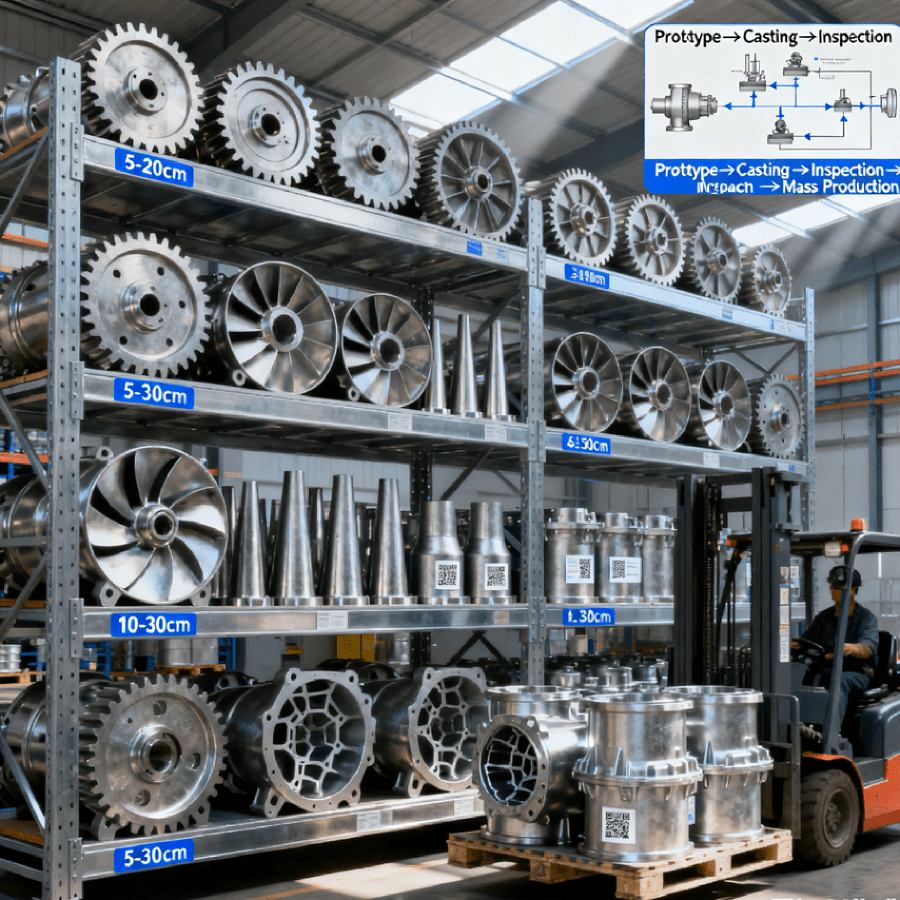

- Sømløs integrering gjennom hele prosessen, som forkorter produktlanserings-sykluser: Vi tilbyr en komplett tjenestekjede fra prototyping til rask støping, ytelsestesting, forsøksproduksjon, justering og videre til massproduksjon. I prototypetrinnet bruker vi 3D-printede voks- og silikoneformer for rask støping og leverer prøver innen 7–10 dager. I forsøksfasen optimaliserer vi samtidig prosessparametere og formstruktur. I massproduksjonsfasen går vi over til standardiserte produksjonslinjer og oppnår en sømløs overgang fra prototyping til massproduksjon, noe som reduserer den totale syklustiden med 30–40 % sammenlignet med tradisjonelle metoder.

- Nøyaktig tilpasning av flere materialer for å oppfylle ulike driftskrav: Vi støtter støping av en rekke materialer, inkludert rustfritt stål (304/316L), legeringsstål (4140/4340), titanlegering (TC4/GR5), aluminiumslegering (A356/A6061) og høytemperaturlegeringer (Inconel 718/Hastelloy C276). Vi kan anbefale det optimale materialet basert på produktkrav (for eksempel motstand mot høy temperatur, korrosjonsmotstand og høy fasthet). Vårt kvalifiseringsnivå for sammensetning av støpemateriale overstiger 99,5 %.

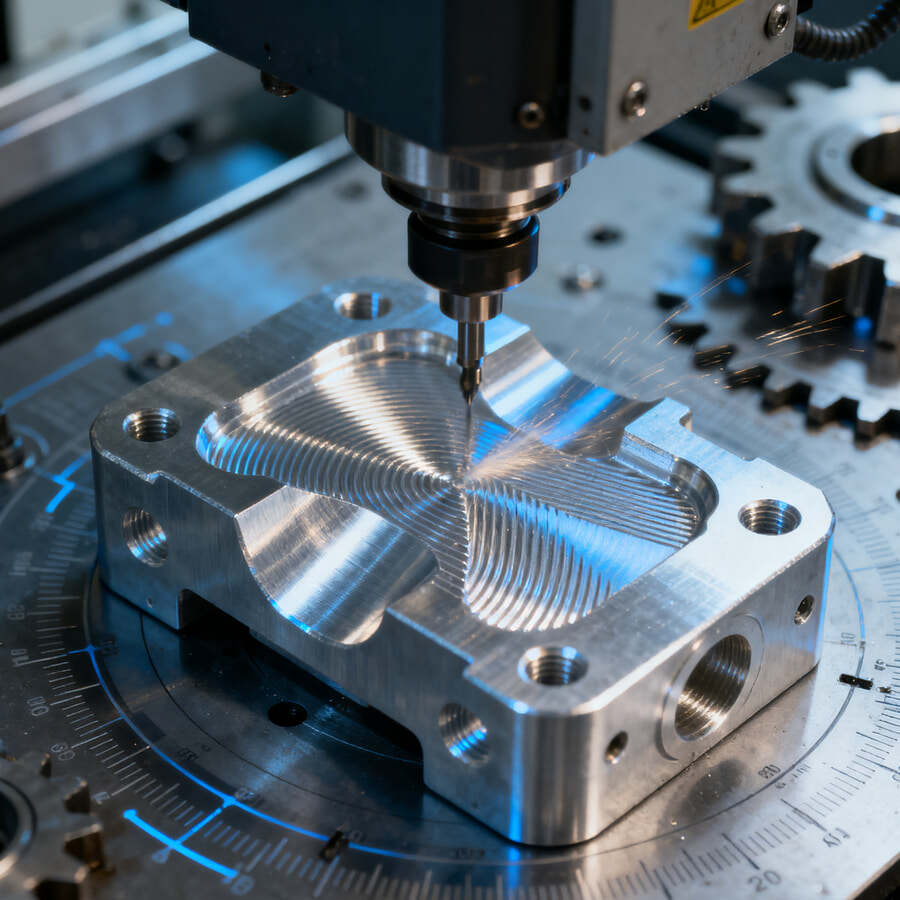

- Presisjonsformkontroll og ytelsesgaranti for å møte krav til høy kvalitet: Ved bruk av prosesser som presisjonsstøping og sandstøping oppnår støpte deler dimensjonell nøyaktighet på CT4–CT7 (i henhold til ISO 8062), overflateruhet Ra ≤ 1,6 μm og viktige geometriske toleranser (som koaksialitet og flathet) innenfor ±0,02–±0,05 mm. Varmebehandling (herding, oppløsning og herding) og ubruddessprøving (røntgeninspeksjon, penetrantprøving) sikrer at mekaniske egenskaper som strekkfasthet og bruddforlengelse oppfyller standardkrav, samtidig som avskretnivået holdes under 2 %.

- Fleksibel produksjonskapasitet og kostnadsoptimalisering for å imøtekomme varierende skala krav: Prototypproduksjon støtter småserielle prøvekjøringer (1–50 enheter), mens massproduksjon kan oppnå en årlig produksjonskapasitet på over 1 million enheter. Utstyrt med flere standardiserte støpeledninger og automatisert rengjøringsutstyr, gir større partier betydelige fordeler i enhetskostnader. Prosesssimulering optimaliserer støpekonstruksjon (for eksempel ved å redusere størrelsen på inngate og risere og optimalisere veggtykkelsesfordeling), reduserer materieltap (≤5 %) og ytterligere kontrollerer produksjonskostnader.

II. Kjerne Anvendelse Områder

(I) Luft- og romfart

- Motor- og romskipskomponenter: Investeringstøping av høytemperaturlegering (Inconel 718) motorblad, titaanlegering (TC4) romskipsskrog kobledder, med temperaturmotstand opp til 650–800 ℃ og strekkfasthet på ≥900 MPa, som oppfyller ekstreme driftsbetingelser i luft- og romfart; presisjonstøping av rustfritt stål (316L) elektronikkbokser for fly, vann- og korrosjonsbestandige, med dimensjonsnøyaktighet på CT5-nivå.

(II) Bil- og ny energisektor

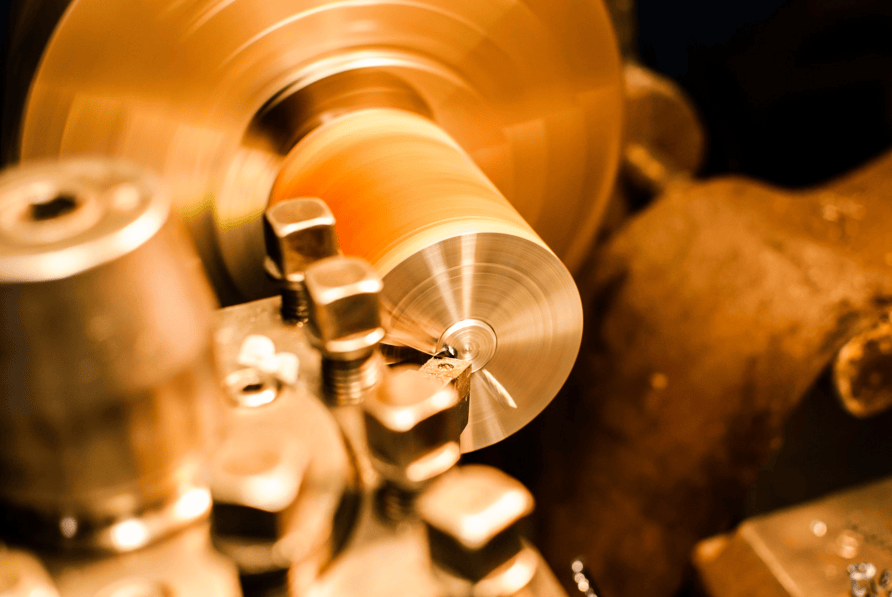

- Kraftoverføringsdelskomponenter: Presisjonstøping i sandform av aluminiumslegering (A356) turbooppladerhus, legeret stål (4140) trekkstenger, med tøtningsgrad på ≥99,8 %, noe som reduserer effekttap; tøping av rustfritt stål (304) batterihylser til nye energibiler, med lettviktsdesign (30 % lettere enn stål) og utmerket slagstyrke.

(III) Energisektor og industriell utstyrsbransje

- Energiprosjektkomponenter: Støpt nikkelbasert legering (Hastelloy C276) kjemisk reaktorpropell, med god korrosjonsbestandighet og tilpasningsevne til sure og alkaliske medier; presisjonsstøpt rustfritt stål (316L) vindturbinflens, med dimensjonell nøyaktighet CT6, som sikrer nøyaktig tilkobling til tårnet.

- Industrielle maskindeler: Presisjonsstøpt legeret stål (4340) girkassehus, aluminiumslegering (A6061) slyngeslidd for verkstedmaskiner, støpeoverflaten kan monteres uten sekundær bearbeiding, noe som forbedrer utstyrets

produksjons-effektivitet.

(IV) Medisinske og høyteknologiske utstyrsområder

- Medisinske utstyrsdeler: Presisjonsstøpt titanlegering (GR5) kunstige ledd, rustfritt stål (316L) hus for kirurgiske verktøy, med god biokompatibilitet og overflateruhet Ra≤0,8 μm, i henhold til medisinske hygienekrav.

- Høykvalitets instrumentkomponenter: Presisjonsinstrumentbase i støpt aluminiumslegering (ADC12), sensorhus i rustfritt stål (304), med dimensjonell nøyaktighet CT5, som sikrer stabil deteksjonsnøyaktighet for instrumentet.

III. Kjernteknologisk støtte

- Fullprosess design og simulering: 3D-modellering av støping utføres ved hjelp av UG og Pro/E. MAGMASOFT-støpesimuleringsprogramvare brukes til å simulere fyllings- og fastningsprosesser, og forutsi feil som krympehulrom og revner. Dette gjør det mulig å foreoptimalisere inngate- og løpere-system samt prosessparametere, noe som resulterer i en førstegangsutbytte på over 98 %.

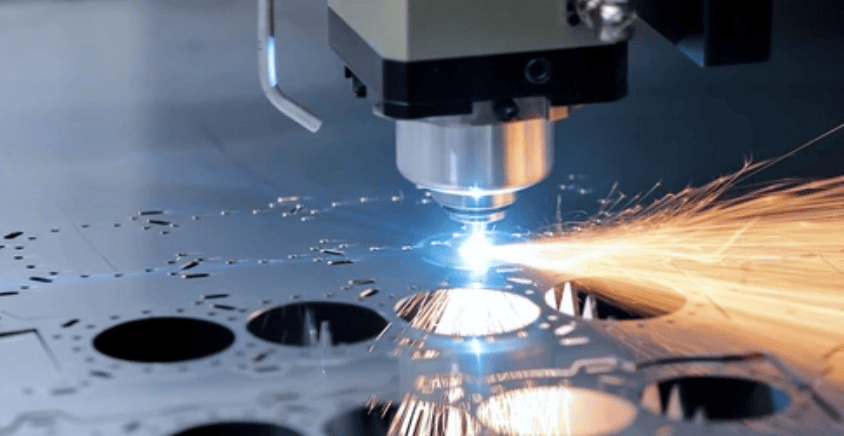

- Flere dimensjoner presisjonsstøpeprosesser:

- Smeltstøping: Egnet for komplekse, tynnveggede deler (minimum veggtykkelse 0,8 mm) og høypresisjonsdeler (CT4–CT6 klasse), som flymotorblad og medisinske ledd;

- Sandpresisjonsstøping: Ved bruk av harskformet sand er dette egnet for mellomstore til store støpte deler (maksimal vekt 500 kg) og masseproduserte deler, som turbinhus for biler og flenser for vindturbiner;

- Rask støping: Kombinerer voks- og sandformsstøping med 3D-printing, hvor prototyper kan leveres allerede etter 7–10 dager, uten behov for verktøyproduksjon og reduserer utviklingskostnader. - Strikt kvalitetsinspeksjonssystem:

- Materialetesting: Spektrometre bekrefter sammensetning, strekktester og hardhetstester kontrollerer mekaniske egenskaper;

- Ikkedestruktiv testing: Røntgen (RT), ultralydtesting (UT) og penetranttesting (PT) sikrer oppdagelse av indre feil;

- Dimensjonsinspeksjon: Koordinatmålemaskiner (nøyaktighet ±0,001 mm) og blålys-skannere utfører fullstendige dimensjonskontroller i henhold til ISO 8062-standarder.

- Digital produksjonsstyring: Et MES-system innføres for å sikre full prosesssporbarhet fra ordre til levering, med sanntidsovervåking av nøkkelparametere som støpetemperatur og trykk. Automatiserte rengjøringslinjer (strålesprengning og polering) og robotisert sortering er også utstyrt for å forbedre effektiviteten i masseproduksjon og produktkonsistensen.

IV. Ofte stilte spørsmål (FAQ)

- Spørsmål: Hva er gjennomføringstiden for prototyper i presisjonsstøping? Hvilke designopplysninger kreves?

Svar: Leveringstid for prototype er 7–10 dager. Det kreves en 2D-teknisk tegning (med toleranser markert) eller en 3D-modell (STEP/IGS-format). Hvis du har spesielle krav til ytelse (for eksempel motstand mot høy temperatur eller korrosjon), vennligst angi disse samtidig. Vi vil anbefale passende materialer og prosesser.

- Spørsmål: Hva er forskjellene i bruksområdene for ulike støpeprosesser? Hvordan velger jeg?

A: Støping ved investering er egnet for komplekse, høypresisjons smådelar (som blad og ledd); sandstøping er egnet for mellomstore til store deler i masseproduksjon (som turbinhus og flenser); og rask støping er egnet for R&D-prototyper eller små serieprøver. Vårt prosesslag kan anbefale den optimale løsningen basert på delens størrelse, kompleksitet, seriestørrelse og presisjonskrav.

- Sp: Hvilken dimensjonell nøyaktighet og overflaterynhet kan oppnås for støpte deler? Kreves det sekundær bearbeiding?

A: Dimensjonell nøyaktighet kan nå CT4–CT7-nivå, med en overflateruhet på Ra ≤ 1,6 μm. For kritiske overflater med ekstremt høye presisjonskrav (som f.eks. monteringsflater), tilbyr vi etterfølgende CNC-bearbeidingstjenester for å sikre at de oppfyller kravene til samling. Ikke-monteringsflater trenger vanligvis ikke sekundær bearbeiding og kan brukes direkte. – Q: Hva er minimumsbestillingsmengde for masseproduksjon? Kan vår produksjonskapasitet håndtere hastebestillinger?

A: Det er ingen streng minimumsbestillingsmengde for masseproduksjon, og vi støtter bestillinger fra 100 til 1 million enheter. Vår årlige produksjonskapasitet overstiger 1 million enheter, og vi har tre støpeledninger som opererer parallelt. Vi kan justere vår produksjonskapasitet for å møte hastebestillinger, noe som tillater akselerert levering innen 15–20 dager (avhengig av bestillingsvolum).

– Q: Kan dere levere kvalitetsrapporter og samsvarserklæringer for støpninger?

A: Ja! Hver parti følges av materiellinspeksjonsrapporter, rapporter for ikke-destruktiv testing og måleinspeksjonsrapporter. For luftfart, medisinsk utstyr og andre felt kan vi levere sertifikater for bransjesamsvar som AS9100 og ISO 13485 for å sikre at våre produkter oppfyller kundens bransjestandarder.