- Oversikt

- Relaterte produkter

I. Kjerne Tjeneste Fordeler

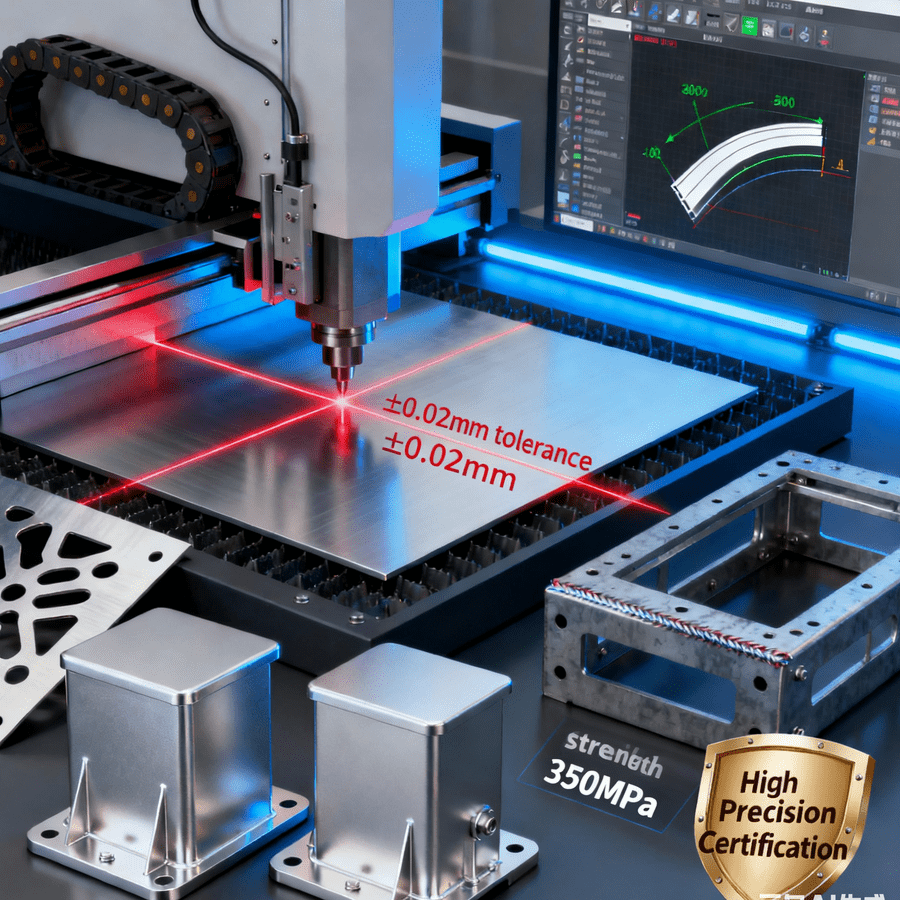

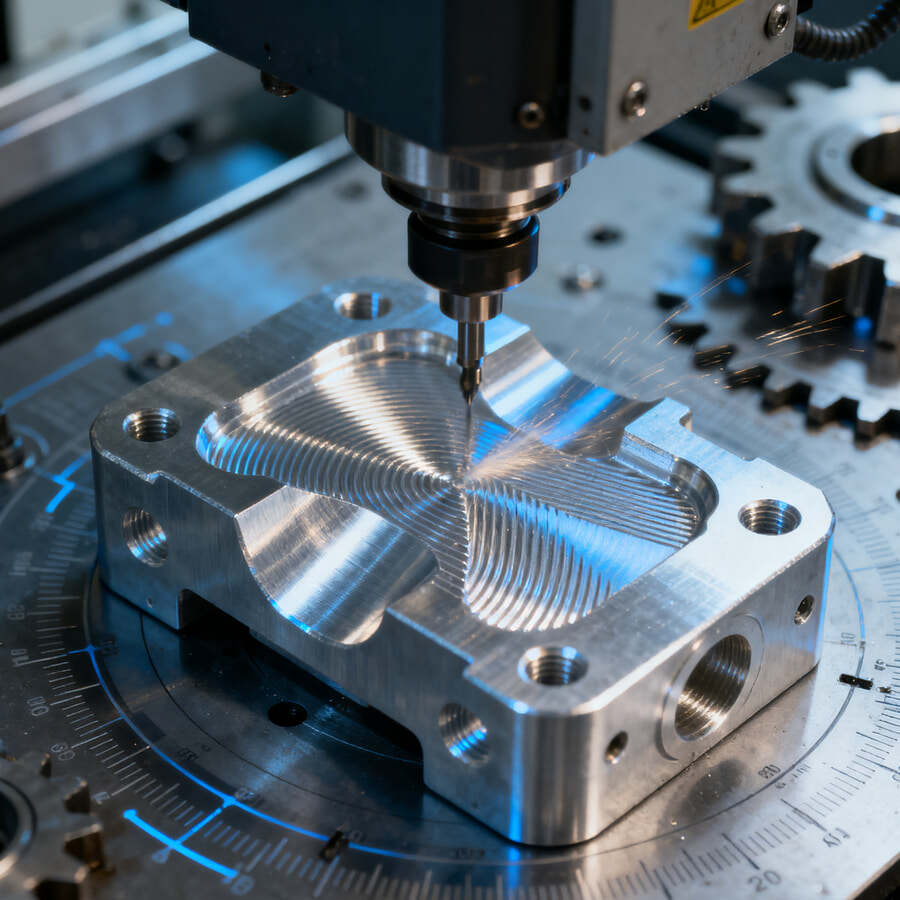

- Mikronivå presisjonskontroll og stramme toleranser: Laserkapping nøyaktighet oppnår ±0,02 mm, bøying av vinkel toleranse ±0,1° og hullposisjonering nøyaktighet ±0,03 mm, noe som oppfyller kravene til montering av presisjonsdeler. Standardiserte prosesser og et system for førsteprosjektinspeksjon sikrer dimensjonskonsistens for deler i masseproduksjon over 99,5 %, noe som reduserer omfattende arbeid ved montering på grunn av presisjonsavvik.

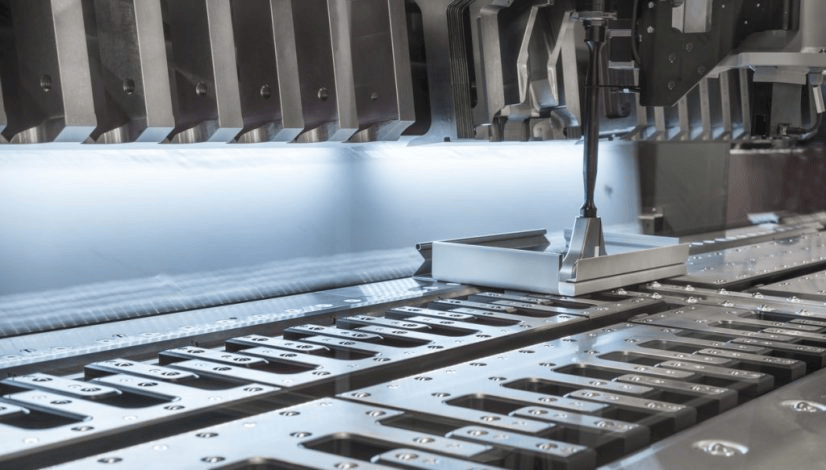

- Fullt integrert tjenestestrøm forenkler leverandørkjeden: Vi tilbyr en integrert prosessflyt som omfatter «laserkapping - CNC-bøyning - presisjonslasing - overflatebehandling - montering», noe som eliminerer behovet for at kunder skal samarbeide med flere leverandører. Utstyrt med automatiske lasting- og lossingsanlegg og et prosessintegreringssystem forkortes bearbeidingstidene med 25–30 % sammenlignet med desentralisert utsetting, samtidig som transporttap og kommunikasjonskostnader reduseres.

- Multimaterialkompatibilitet, tilpasset ulike arbeidsforhold: Støtter bearbeiding av ulike materialer, inkludert rustfritt stål (304/316L), karbonstål (Q235/Q355), aluminiumslegering (6061/5052), forzinket plate og galvanisert plate, med tykkelser fra 0,1 til 12 mm. Det optimale materialet anbefales basert på delens tenkte bruk (f.eks. korrosjonsbestandighet, høy fasthet, lettvekt), og skreddersydde prosessparametere tilpasses for å sikre produkter av høy kvalitet.

- Dannelse av komplekse strukturer for å møte spesialbehov: I stand til å bøye komplekse kurvede flater, utføre sveising i flere stasjoner og kutte særformede hull, kan det bearbeide komplekse platemetalldeler, inkludert rettvinklede og buede bøyninger, kassestrukturer og rammekomponenter. For komplekse strukturer hjelper 3D CAD-modellering og prosesssimulering med forhåndsvisning på å unngå formasjonsfeil på forhånd, og sikrer en gjennomløpsrate på over 98 %.

II. Kjerne Anvendelse Områder

(I) Industriutstyr

- Utstyrshus og skjold: Vi produserer rustfrie stål 304 utstyrshus med laserkutting av nøyaktige hull (åpningstoleranse ±0,05 mm), deretter bøying og formasjon med slipeslutt for både rustresistens og estetikk. Vi tilpasser også karbonstål-utstyrsskjold med ribbet design for økt stivhet, for å oppfylle beskyttelseskravene til slyngemaskiner og automatisert utstyr.

- Interne strukturdelar: Vi produserer aluminiumslegering 6061 utstyrsbraketter og koblinger, med lettviktsdesign (40 % lettere enn karbonstål) og garantert fasthet. Presis bøying sikrer nøyaktig montering med andre komponenter, noe som reduserer vibrasjoner under utstyrets drift.

(II) Ny energi

- Battyrikabinetter og festekonstruksjoner: Vi tilpasser galvaniserte stålbattyrikabinetter, der vi bruker laserskjæring og deretter bøying. Vi svelger dem med pulsargongassveising, noe som resulterer i glatte, tette sømmer og IP65-beskyttelse. Vi produserer også karbonstål-battystøtter ved hjelp av CNC-bøying for å sikre hulljustering, noe som letter rask installasjon av battymoduler.

- Fotonvandler-tilbehør: Vi produserer tilkoblinger i 5052 aluminiumslegering for fotonvendere, med utmerket korrosjonsmotstand og en bøyevinkelnøyaktighet på ±0,1°, noe som sikrer jevn og stabil installasjon av støtter, egnet for langvarig utendørs bruk.

(III) Kommunikasjon og 3C-elektronikk

- Tilbehør til kommunikasjonsbasestasjoner: Vi bearbeider 316L rustfrie stål deksler til basestasjonsantenne, laserkuttet for nøyaktig å reservere signalfelter, og vi påfører en passiveringsbehandling på overflatene etter bøying for å beskytte mot UV-stråler, vind og regn. Vi tilpasser også kabinettstel med karbonstål til basestasjoner, som er sveist og polert for å sikre strukturell stabilitet og lette installasjon av innvendig utstyr.

- Hus til 3C-utstyr: Vi produserer 6061 aluminiumslegering holder til laptop og printertilbehør med tynnveggbøying (minimum veggtykkelse 0,8 mm) med en nøyaktighet på ±0,03 mm. Våre overflater er anodisert for forbedret struktur og slitasjebestandighet.

III. Kjernteknologisk støtte

- Høypresisjons bearbeidingsutstyr: Utstyrt med en tysk TRUMPF TruLaser 5030 fiberlaser-skjæremaskin (skjæringshastighet opp til 30 m/min, posisjoneringsnøyaktighet på ±0,015 mm), en japansk Amada RG-100 CNC-bøyemaskin (6-akse bøying, repeterbarhet på ±0,005 mm) og en sveiserobot fra den sveitsiske Bystronic, som sikrer stabil presisjon i hver prosess.

- Digital prosessystem: Ved bruk av SolidWorks og AutoCAD for 3D-modellering og utvikling, kobles ordre til prosesparametere via ERP-systemet. Automatisk programmeringsprogramvare for bøyesekvens genererer automatisk bøyesekvenser og kompenseringsparametere basert på delens form, noe som reduserer feil forårsaket av manuell innblanding.

- Overflatebehandling og kvalitetsinspeksjon: Vi tilbyr overflatebehandlinger som spraying (pulver/væske), børsting, passivering, anodisering og galvanisering. Alle prosesser er i samsvar med RoHS miljøstandarder. Under kvalitetsinspeksjonsprosessen bruker vi en tredimensjonal koordinatmålemaskin (nøyaktighet ±0,001 mm), et 2D-bildevåpen og en strekktester for å grundig kontrollere mål, sveisekraft og materialeegenskaper.

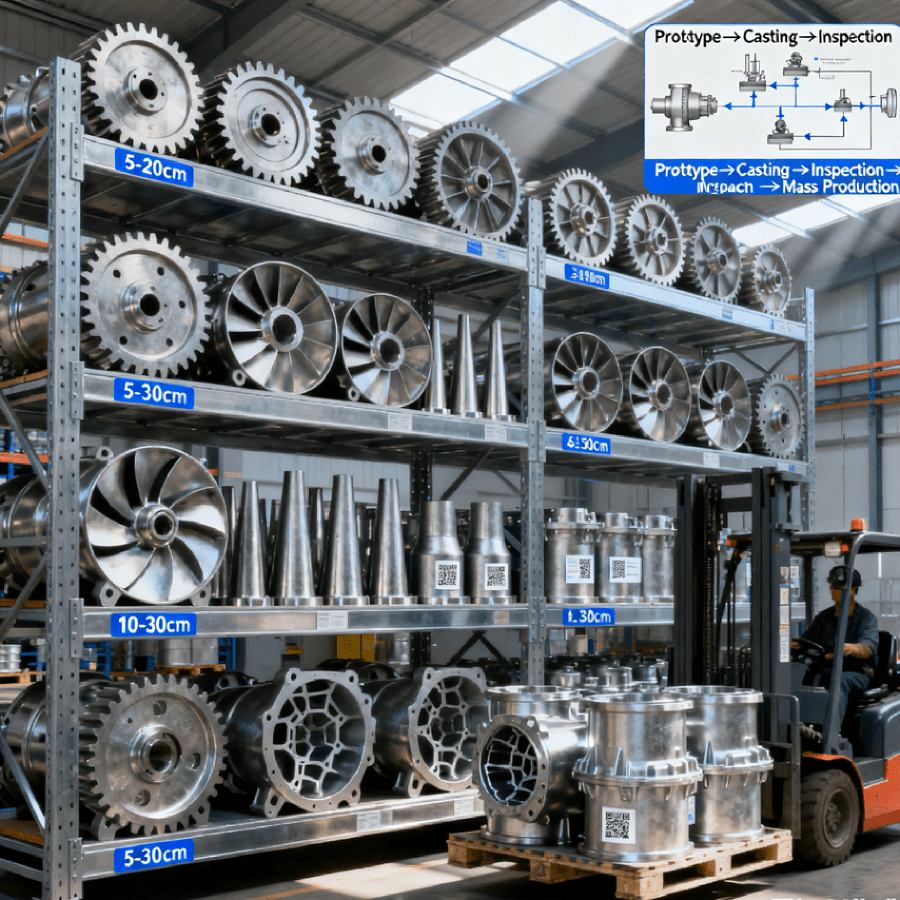

- Fleksible produksjonsmuligheter: Vi har etablert en fleksibel produksjonslinje som støtter skifte mellom småserietilpassing (1–50 stykker) og storstilt masseproduksjon (10 000+ stykker). Småserieordrer benytter rask omstillingsmodellteknologi, som reduserer omstillings tid til under 30 minutter. Store serier produseres på automatiserte monteringslinjer, med en daglig produksjonskapasitet på over 5 000 stykker.

IV. Vanlige spørsmål (FAQ)

- Spørsmål: Hva er den minste nøyaktigheten som oppnås i bearbeiding av platemetall? Er det forskjeller i nøyaktighet for ulike materialer?

Svar: Den minste nøyaktigheten for laserskjæring er ±0,02 mm, og minste vinkeltoleranse for bøying er ±0,1°. Nøyaktigheten varierer noe avhengig av materialets seighet og hardhet. For eksempel er bøyingsnøyaktigheten for aluminiumslegering litt høyere enn for karbonstål, men alle materialer oppfyller grunnkravet til toleranse på ±0,1°. Detaljerte spesifikasjoner for nøyaktighet kan leveres basert på materialet.

- Spørsmål: Hvilke hensyn bør tas når man designer komplekse platekonstruksjoner? Kan dere gi forslag til designoptimalisering?

A: Designet bør legge vekt på bøyeradius (anbefalt ≥1,5 ganger platetykkelsen), hullavstand (≥1,2 ganger platetykkelsen) og sveisingstoleranse. Vi kan tilby tjenester for designoptimalisering, som f.eks. sammenslåing av deler for å redusere antall sveiseoperasjoner og optimalisering av bøyesekvens for å unngå kollisjoner, og dermed redusere produksjonsvanskeligheter og kostnader.

- Sp: Hvilke overflatebehandlingsprosesser er tilgjengelige for platemetaldeler? Hvordan velger jeg den rette?

A: Vanlige prosesser inkluderer pulverlakk (utmerket værbestandighet og rike farger), anodisering (egnet for aluminiumslegeringer og gir god struktur), passivering (rustbeskyttelse av rustfritt stål) og galvanisering (rustbeskyttelse av karbonstål). Du kan velge basert på bruksmiljø (f.eks. utendørs/innendørs, korrosive forhold) og estetiske krav, og vi vil gi tilpassede anbefalinger.

- Sp: Hva er gjennomføringstiden for små og store ordre? Støtter dere ekspresproduksjon?

A: Småordrer (1–50 stk) har en ledetid på 3–5 dager; store ordrer (1 000+ stk) har en ledetid på 7–10 dager. Vi støtter også hastordrer, med expediert levering innen 24–48 timer via kapasitetsallokering (avhengig av ordrens kompleksitet og kvantum).

- Spørsmål: Kan dere levere prøveproduksjon av prøver? Vil dere gå videre til masseproduksjon etter at prøvene er godkjent?

A: Ja! Vi kan først produsere 1–3 prøver. Når kunden har bekreftet målenøyaktighet, overflatekvalitet og ytelse, kan vi starte masseproduksjon. Prøveproduksjon av prøver tar 2–3 dager. I løpet av prøveproduksjonsprosessen kan vi justere prosessparametere basert på tilbakemeldinger for å sikre at det endelige produktet oppfyller forventningene.