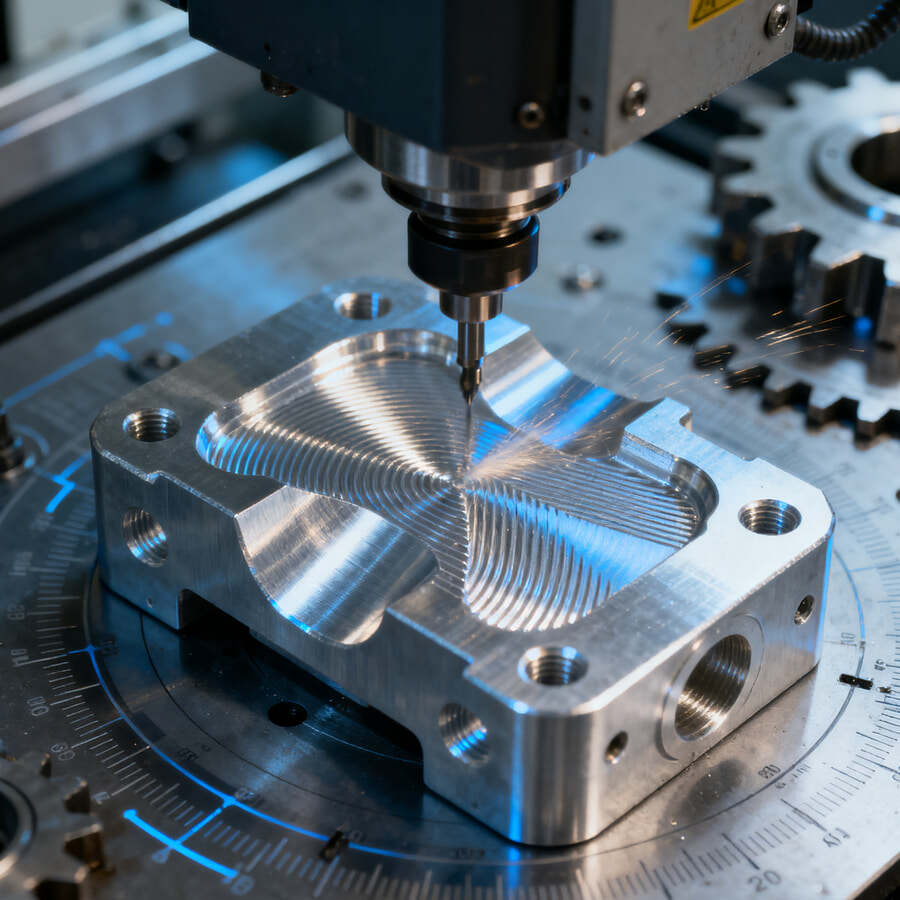

Servizio di fresatura CNC a quattro assi ad alta precisione - adatto per parti personalizzate in lega di alluminio e acciaio inossidabile, tipo scatola/guscio

- Panoramica

- Prodotti correlati

1. Vantaggi principali del servizio

Lavorazione precisa multi-dimensionale, in grado di gestire strutture complesse di scatole/involucri

Utilizzando un sistema CNC a quattro assi collegati (movimento lineare sugli assi X/Y/Z + movimento rotativo sull'asse A), le parti della scatola/carcassa possono essere bloccate in un'unica soluzione e lavorate in diversi modi, senza necessità di ripetere il posizionamento, riducendo notevolmente gli errori di serraggio. La precisione di posizionamento può raggiungere ± 0,003 mm, mentre la ripetibilità del posizionamento può essere di ± 0,002 mm. Per strutture complesse quali fori nelle pareti laterali, scanalature inclinate e cave anulari della scatola/carcassa, la fresatura può essere completata in un'unica lavorazione, evitando deviazioni dimensionali causate da tradizionali processi multipli, garantendo che la tenuta e la precisione di assemblaggio di scatole/carcasse in lega di alluminio e acciaio inox rispettino gli standard di progettazione.

Adattamento specifico di materiali e tecnologie, bilanciando le caratteristiche dei materiali e l'efficienza di lavorazione

Casella/conchiglia in lega di alluminio: in risposta alle caratteristiche leggere e facilmente deformi termiche della lega di alluminio, vengono utilizzate la tecnologia di taglio a bassa temperatura e macchine specializzate per il rivestimento delle estremità per ridurre lo stress termico durante il processo di lavorazione, evitare la deformazione delle par

Scatola/conchiglia in acciaio inossidabile: in risposta all'elevata resistenza e durezza dell'acciaio inossidabile (come l'acciaio inossidabile 304/316), è dotato di strumenti di taglio ad alta velocità di leghe dure e di un sistema di raffreddamento ad alta pressione Può raggiungere una precisione di liscezza di Ra ≤ 0,8 μm sulla superficie della scatola/conchiglia, soddisfacendo i requisiti di resistenza alla corrosione e all'usura.

Copertura flessibile di personalizzazione, adattata per soddisfare le esigenze di più scene

Supporta la personalizzazione completa dello scenario da "produzione di prova su piccola scala (1-50 pezzi) " a "produzione di massa su larga scala (1000+ pezzi)". Sia che si tratti di piccoli equipaggiamenti elettronici con gusci in lega di alluminio (come gli alloggiamenti dei sensori), di chassis in acciaio inossidabile di controllo industriale di medie dimensioni o di scatole/gusci di attrezzature speciali con strutture irregolari, possono essere rapidamente smontati e lavor

Controllo della qualità dell'intero processo per garantire prestazioni stabili delle scatole/conchiglie

Stabilire un sistema di controllo a tre livelli per i requisiti funzionali principali "portante, sigillatura e protezione" dei componenti a scatola/carcassa, inclusi "analisi dei materiali prima della lavorazione → monitoraggio in tempo reale durante la lavorazione → ispezione completa della qualità dopo la lavorazione": verificare la composizione dei materiali in lega di alluminio/acciaio inossidabile (ad esempio la durezza della lega di alluminio 6061-T6 e la resistenza alla corrosione dell'acciaio inossidabile 316) prima della lavorazione; Compensazione in tempo reale dell'usura degli utensili attraverso il sistema CNC durante la lavorazione; Dopo la lavorazione, utilizzare un apparato di misura a coordinate per controllare la tolleranza dei fori, la planarità e la perpendicolarità della scatola/carcassa per garantire che ogni prodotto rispetti gli standard di utilizzo.

2、 Principali settori applicativi

Industria Elettronica e delle Telecomunicazioni

Telaio personalizzato in lega di alluminio per apparecchiature di comunicazione (ad esempio alloggiamento del ricevitore del segnale della stazione base 5G), telaio per interruttore industriale in acciaio inossidabile, la lega di alluminio soddisfa i requisiti di leggerezza, il materiale in acciaio inossidabile resiste alla corrosione in ambienti difficili ed è adatto all'assemblaggio preciso dei componenti interni dell'apparecchiatura.

Campo dell'automazione industriale

Produciamo armadi di controllo PLC in acciaio inossidabile e custodie protettive in lega di alluminio per sensori. La fresatura a quattro assi può lavorare con precisione fori per cavi e scanalature di installazione delle scatole/carcasse, garantendo connessioni elettriche stabili e un assemblaggio senza interruzioni dei componenti dell'equipaggiamento automatizzato.

Industria degli equipaggiamenti medici

Lavorazione di involucri per strumenti diagnostici in acciaio inossidabile (ad esempio involucri per analizzatori del sangue) e involucri per carrelli medicali in lega di alluminio. L'acciaio inossidabile rispetta gli standard igienici per uso medico (facile da pulire, resistente alla corrosione), mentre la lega di alluminio è leggera e facile da spostare. Allo stesso tempo, la struttura di tenuta dell'involucro protegge gli strumenti interni da polvere e interferenze liquide.

settore delle Nuove Energie

Corpo personalizzato in lega di alluminio per colonnine di ricarica e involucro in acciaio inossidabile per apparecchiature di accumulo di energia. La dissipazione del calore della lega di alluminio è adatta all'ambiente di lavoro ad alta temperatura delle colonnine di ricarica. L'elevata resistenza dell'acciaio inossidabile protegge l'apparecchiatura di accumulo da impatti esterni. La struttura lavorata a quattro assi con scanalature impermeabili può migliorare il livello di protezione IP65 della scatola/involucro.

AAE Aerospace Ancillary Auxiliary Equipment

Produzione di involucri per apparecchiature aeroportuali in lega di alluminio e involucri per strumenti di test aeronautici in acciaio inossidabile. La leggera lega di alluminio può ridurre i costi di trasporto delle apparecchiature, mentre l'acciaio inossidabile ad alta resistenza è adatto per ambienti estremi come alta quota e basse temperature. La struttura precisa dell'involucro/carcassa soddisfa le rigorose esigenze di precisione del settore aerospaziale.

3. Supporto tecnico principale

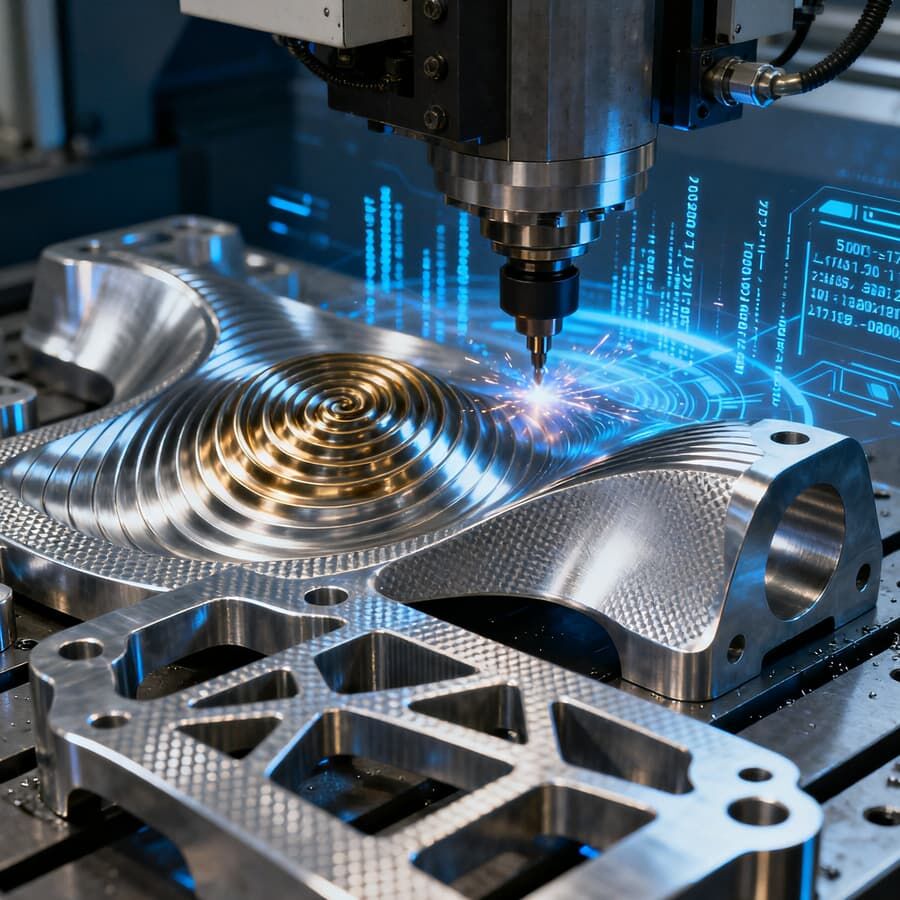

Sistema CNC a quattro assi ad alte prestazioni

Dotato di sistema CNC a quattro assi Siemens 828D/Fanuc 0i-MF, supporta la generazione automatica di percorsi di lavorazione per superfici complesse e può realizzare un controllo sincronizzato tra l'asse A (asse rotante) e gli assi X/Y/Z. Durante la lavorazione di scanalature anulari e fori inclinati su scatole/carcasse, l'errore di precisione di posizionamento è ≤ 0,003 mm. Allo stesso tempo, il sistema dispone di funzione di autodiagnosi dei guasti e può fornire avvisi in tempo reale su anomalie di lavorazione (ad esempio rottura utensile e deviazione del materiale).

Struttura di macchina utensile ad alta rigidezza

Il letto della macchina utensile adotta un processo di fusione integrale in ghisa, che elimina le tensioni interne e riduce le vibrazioni durante la lavorazione grazie a due trattamenti di invecchiamento; La mandrino è dotato di cuscinetti ceramici di alta precisione, con una velocità massima di 12000 giri/min. Può fornire una potenza di taglio stabile per scenari di taglio pesante di scatole/carcasse in acciaio inossidabile, evitando deviazioni di precisione di lavorazione causate da vibrazioni del mandrino.

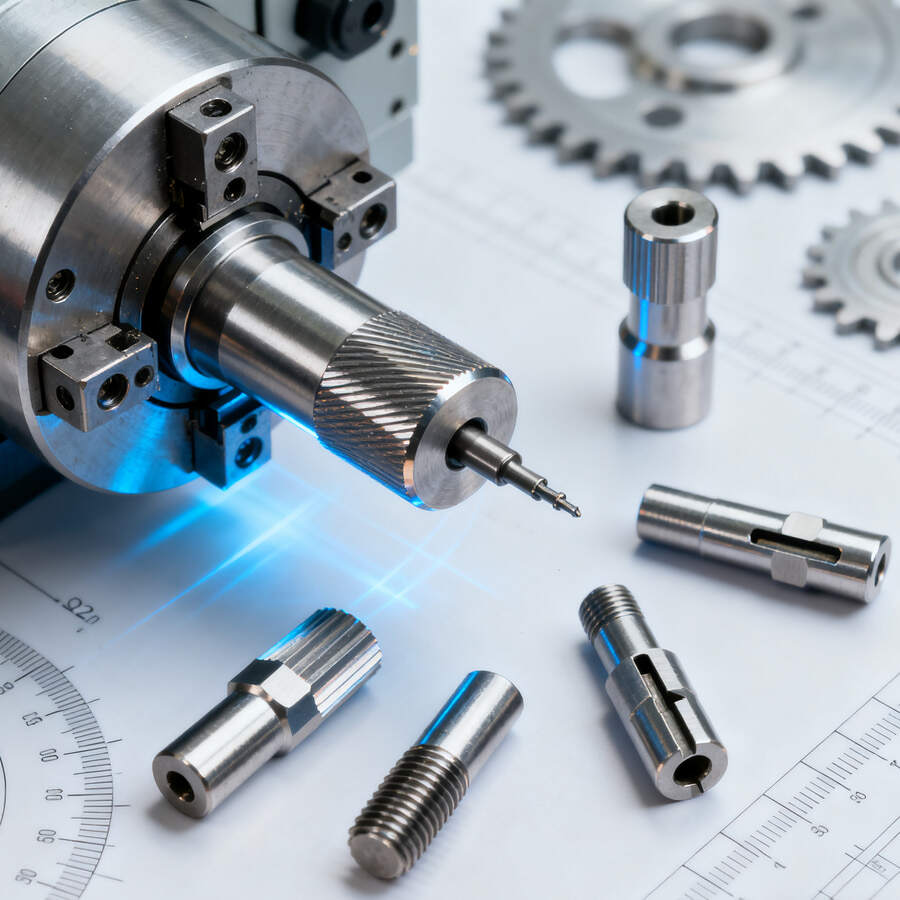

Utensili da taglio specializzati e sistema di raffreddamento

Utensili: vengono utilizzati frese a tazza rivestite in acciaio tungsteno per la lavorazione di scatole/carcasse in lega di alluminio (con un aumento del 30% della resistenza all'usura), mentre utensili in lega dura a grana ultrafine vengono utilizzati per la lavorazione di scatole/carcasse in acciaio inossidabile (con elevata resistenza agli urti e ridotta rottura dell'utensile);

Sistema di raffreddamento: dotato di un sistema di raffreddamento interno ad alta pressione (pressione di raffreddamento fino a 70 bar), può rimuovere rapidamente il calore generato durante la lavorazione dell'acciaio inossidabile, evitare il surriscaldamento e l'usura degli utensili e prevenire la deformazione delle scatole/carcasse in lega di alluminio dovuta alle alte temperature.

Gestione del Processo di Lavorazione Digitale

Introduzione del sistema di esecuzione produttiva MES per realizzare la tracciabilità digitale dell'intero processo di lavorazione della scatola/carcassa: una volta ricevuti gli ordini dei clienti, il sistema genera automaticamente gli ordini di lavoro e assegna le risorse delle macchine; raccolta in tempo reale dei parametri operativi delle attrezzature durante il processo (ad esempio velocità del mandrino e avanzamento del taglio); al termine della lavorazione, viene generato automaticamente un rapporto di controllo qualità e i clienti possono visualizzare in qualsiasi momento l'avanzamento dell'ordine e i dati dei test sui prodotti.

4. Domande frequenti (FAQ)

Q: Qual è la dimensione massima di lavorazione per scatole/gusci personalizzati in lega di alluminio/acciaio inox? Possiamo supportare la lavorazione di scatole/gusci di dimensioni extra?

A: La gamma di dimensioni convenzionali è di 1000 mm in lunghezza, 600 mm in larghezza e 500 mm in altezza. Se necessari, per scatole/gusci extra large (ad esempio con lunghezza superiore a 1500 mm) possono essere fornite soluzioni personalizzate di lavorazione tramite tecnologie di lavorazione segmentata e assemblaggio preciso. La fattibilità può essere confermata dagli ingegneri tecnici.

Q: Esiste una differenza nel ciclo di lavorazione tra scatole/gusci in lega di alluminio e scatole/gusci in acciaio inox? In quanto tempo possono essere consegnati gli ordini standard?

A: A causa della maggiore difficoltà di lavorazione dell'acciaio inossidabile (durezza elevata, tendenza ad appiccicare le lame), il ciclo di lavorazione dell'acciaio inossidabile per contenitori/carcasse con la stessa struttura è del 15%-20% più lungo rispetto a quello dell'alluminio; Per ordini regolari di piccole quantità (1-50 pezzi): i contenitori/carcasse in lega di alluminio possono essere consegnati entro 7-10 giorni, mentre i contenitori/carcasse in acciaio inossidabile entro 10-12 giorni; Per grandi ordini (1000+ pezzi) è possibile abbreviare i tempi attraverso la produzione parallela di più macchine, e i tempi di consegna specifici possono essere concordati in base alla quantità dell'ordine.

D: Quali sono i requisiti per lo spessore delle pareti durante la personalizzazione di contenitori/carcasse? È possibile lavorare strutture con pareti ultrasottili o molto sottili?

A: Intervallo di spessore convenzionale: scatola/guscio in lega di alluminio ≥ 1 mm, scatola/guscio in acciaio inossidabile ≥ 0,8 mm; per pareti ultra-sottili (ad esempio lega di alluminio ≤ 0,8 mm) è necessario utilizzare dispositivi speciali e controllare la deformazione con tecnologia di taglio a bassa velocità, mentre per pareti ultra-spesse (ad esempio acciaio inossidabile ≥ 20 mm) è necessario utilizzare la tecnologia di fresatura a strati. In entrambi i casi è richiesta una comunicazione preventiva e un design strutturale per garantire la resistenza e la planarità della scatola/guscio dopo la lavorazione.

D: Possiamo fornire servizi di trattamento superficiale per scatole/gusci in lega di alluminio/acciaio inossidabile? Quali processi sono disponibili?

R: Supportiamo servizi integrati di "lavorazione+trattamento superficiale":

Scatola/guscio in lega di alluminio: anodizzazione (colore naturale, nero, colorato), sabbiatura, verniciatura, trafilatura e altri processi disponibili per migliorare la resistenza all'usura e l'estetica;

Scatola/guscio in acciaio inossidabile: processi opzionali come trafilatura, passivazione, elettrodeposizione (zinco, nichel), marcatura laser, ecc., migliorano la resistenza alla corrosione e la chiarezza dell'identificazione.

D: Quali informazioni tecniche sono necessarie per personalizzare scatole/gusci? Se ci sono solo idee preliminari di progettazione, è possibile ricevere assistenza per migliorare il piano?

R: Si consiglia di fornire disegni tecnici 2D (indicanti tolleranze dimensionali, spessore delle pareti, richieste di trattamento superficiale) o modelli 3D (in formato STEP/IGS/X_T); se ci sono solo idee preliminari, possiamo fornire una descrizione delle esigenze (come scenari d'uso, dimensioni dei componenti di assemblaggio, requisiti del livello di protezione), e i nostri ingegneri possono aiutare a completare la progettazione strutturale, la selezione dei materiali, l'analisi di fattibilità dei processi, e produrre una soluzione tecnica completa prima di iniziare la lavorazione.

| Lavorazione | Servizi di Lavorazione CNC: Fresatura CNC, Tornitura CNC, Taglio Laser, Foratura, Piega, Ribalda, Filiere, Stampa, EDM, Lavorazione 3 Assi, 4 Assi, 5 Assi, Macchine Svizzere per Utensili; Servizi Completi di Lavorazione: Metallurgia delle Polveri, Lavorazione Lamiera, Stampa, Fusione in Pressofusione, Stampa 3D, Stampaggio a Iniezione, Prototipazione Rapida, Stampi, Ecc.; Lavorazione Multi-Processo |

| Servizi di Assemblaggio | Fissaggio e Giunzione, Assemblaggio Componenti, Assemblaggio Completo, Imballaggio ed Etichettatura |

| Materiali | Alluminio: serie 2000, serie 6000, 7075, 5052 ecc. |

| Acciaio inossidabile: sus303, sus304, ss316, ss316l, 17-4ph, ecc. | |

| Acciaio: 1214l/1215/1045/4140/cmq440/40crmo, ecc. | |

| Ottone: 260, c360, h59, h60, h62, h63, h65, h68, h70, bronzo, rame | |

| Plastico: acetalo/pom/pa/nylon/pc/pmma/pvc/pu/acrilico/abs/ptfe/peek ecc. | |

| Tolleranza di Precisione | ±0,001mm~±0,005mm Prodotti specifici possono soddisfare le richieste del cliente. |

| Roughness di superficie | Min ra 0, 1 ~ 3, 2 |

| Trattamento superficiale | Anodizzato, Sabbiatura, Serigrafia, Placcatura PVD, Placcatura in Zinco/Nichel/Cromo/Titanio, Spazzolatura, Verniciatura, Pulviscolatura |

| Rivestimento, Sabbiatura, Passivazione, Elettroforesi, Lucidatura Elettrolitica, Scanalatura, Incisione/Laser/Incisione ecc. | |

| Volume di produzione | Basso-Medio Volume, Prototipo e Produzione a Lotti |

| Modalità di elaborazione | Personalizzato Secondo Disegni CAD Forniti |

| Tempo di consegna | Tempi di Consegna Ridotti, Generalmente 1-4 Settimane |

| Controllo Qualità | Severi Processi di Garanzia e Controllo Qualità |

| Imballaggio | Imballaggio Sicuro per Prevenire Danneggiamenti Durante il Trasporto |

| Certificato | ISO9001,AS9100D,ISO45001,ISO14001,ROHS,CE ecc. |

| ordine Minimo di 1 Pezzo | Capacità di Fornire Campioni Prima della Produzione di Serie |