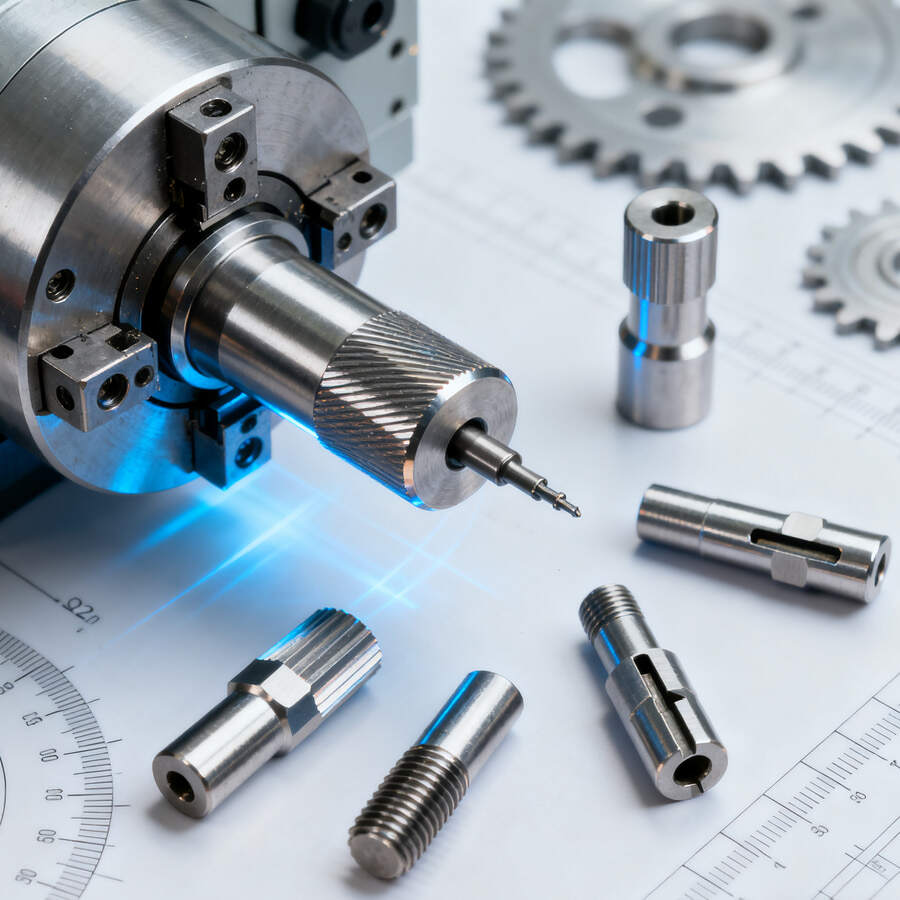

Swiss style precision machining - specializing in high-precision turning and milling of shaft parts with a diameter less than Φ 32mm

- Overview

- Related Products

1、 Core service advantages

Small diameter shaft precise shape control, breaking through the bottleneck of micro size machining

Based on the unique "guide sleeve support+spindle linkage" structure of Swiss style machining, it achieves integrated machining of turning and milling for slender shafts and micro shaft parts with a diameter of ≤ Φ 32mm (minimum machining capacity of Φ 0.5mm). The diameter tolerance can be stably controlled within ± 0.001mm, roundness ≤ 0.0008mm, and surface roughness can reach Ra ≤ 0.2 μ m, perfectly solving the problems of small diameter shafts being prone to vibration and large dimensional deviations in traditional machining. It is suitable for medical, electronic, and other scenarios that require extremely high micro precision.

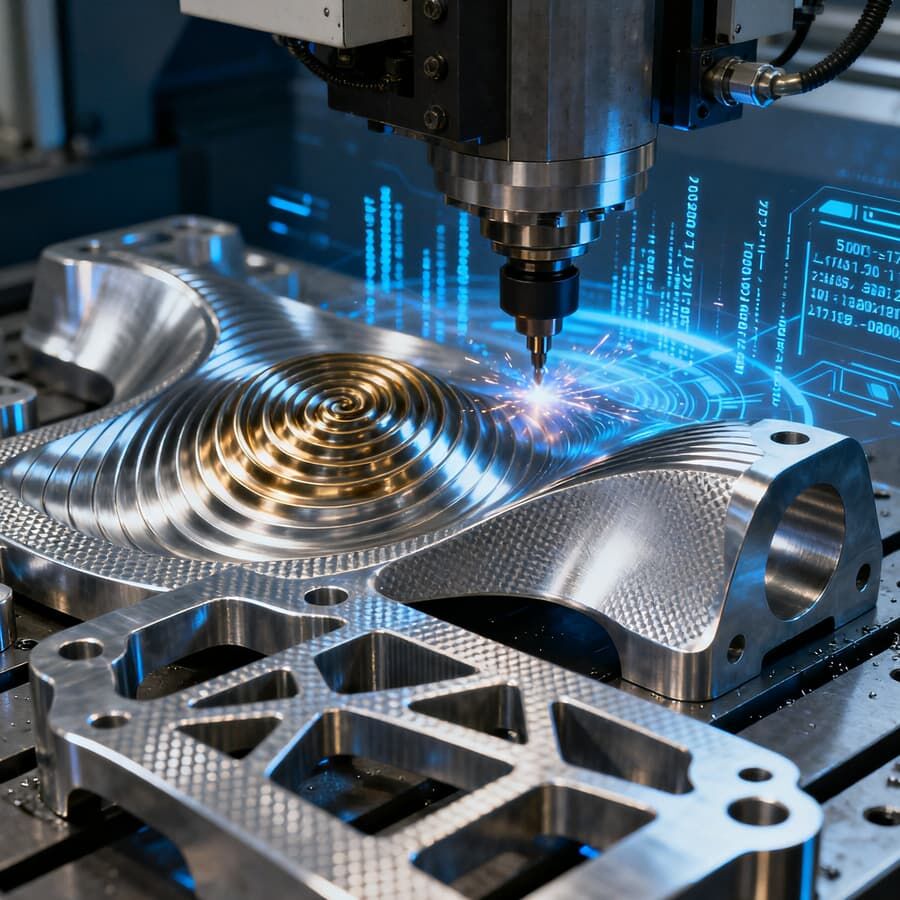

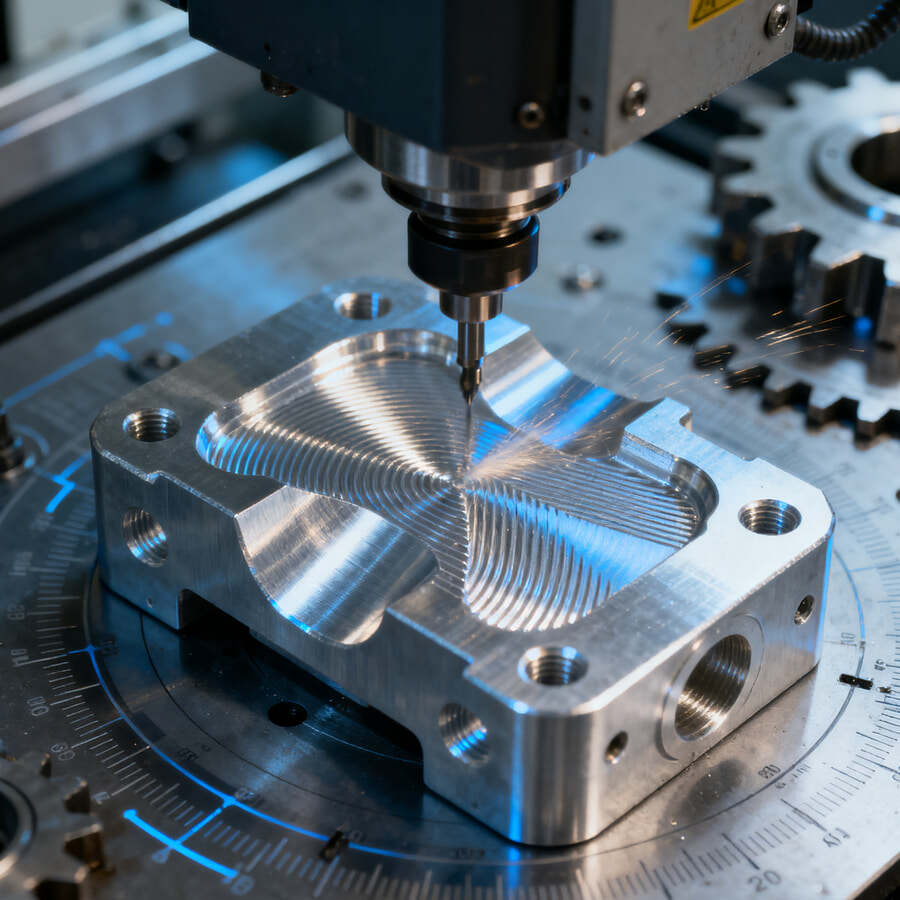

Efficient integration of turning and milling, reducing process costs and improving efficiency

For composite structures such as grooves, holes, threads, chamfers, etc. of shaft parts, multiple clamping is not required. Through the linkage of the "main spindle+auxiliary spindle+multi station milling unit" of the Swiss type centering machine, the processes of turning the outer circle, milling keyways, drilling and tapping can be completed in one go, reducing the process by more than 50% and shortening the processing cycle by 35% -45% compared to traditional lathes. At the same time, avoid cumulative errors caused by multiple positioning, and ensure that the coaxiality (≤ 0.002mm), perpendicularity (≤ 0.003mm), and other key positional tolerances of shaft components meet the standards.

Wide material compatibility, balancing metal and special material processing

Metal materials: customized cutting parameters for commonly used shaft materials such as stainless steel (304/316), titanium alloy (TC4), copper alloy (H62), aluminum alloy (6061-T6), etc. - stainless steel processing is equipped with a high-pressure cooling system (pressure 80 bar) and anti sticking knives, while titanium alloy processing uses low-temperature cutting technology to reduce thermal deformation and ensure the processing stability of shafts with a diameter of ≤ Φ 32mm;

Special materials: Supports the processing of engineering plastic shafts such as PEEK and POM. Through flexible fixtures and low-speed milling processes, plastic shafts are avoided from melting and deforming due to high temperatures, meeting the needs of electronic insulation parts and lightweight medical components.

Batch consistency control ensures stable quality of small and micro shafts

Establish a full process quality control system for "raw materials processing testing": verify the diameter deviation of the material before processing (ensuring that the fluctuation of the raw material diameter is ≤ 0.005mm); Real time compensation of tool wear through CNC system during processing (automatic calibration of tool position for every 100 pieces processed); After processing, a laser caliper (with an accuracy of ± 0.0005mm) and a tool microscope are used to conduct a 100% full inspection of the shaft diameter, groove depth, and thread accuracy. The inspection report is retained for each batch to ensure consistency in mass production.

2、 Core application areas

Medical equipment field

Customized medical catheter shafts with diameters ranging from Φ 1 to Φ 8mm (made of stainless steel/titanium alloy material, smooth and burr free surface), surgical instrument drive shafts (such as biopsy needle core shafts with diameters ranging from Φ 0.8 to Φ 3mm), and diagnostic instrument micro shafts (such as blood glucose meter detection shafts with diameters ranging from Φ 2 to Φ 5mm), with machining accuracy in accordance with medical grade ISO 13485 standards, ensuring safe equipment use.

In the field of electronics and connectors

Produce connector pins with a diameter of Φ 0.5-Φ 6mm (made of copper alloy material, with a turning accuracy of ± 0.001mm), sensor signal shafts (made of aluminum alloy material, with a milling positioning groove accuracy of ± 0.002mm), and micro motor shafts (with a diameter of Φ 3- Φ 12mm and a coaxiality of ≤ 0.002mm) to meet the miniaturization and high integration requirements of consumer electronics and industrial control equipment.

In the field of automotive precision components

Processing of automotive fuel injection system valve core shaft (made of stainless steel with strong wear resistance) with a diameter of 5- Φ 25mm, transmission micro gear shaft (diameter of 8- Φ 15mm, tooth milling accuracy level 6), and automatic driving radar adjustment shaft (made of aluminum alloy with a diameter of 6- Φ 10mm) to meet the high-strength and high reliability requirements of automotive components.

Aerospace micro component field

Customize aviation instrument pointer shafts (made of titanium alloy, lightweight) with diameters ranging from 3 to 18mm, micro transmission shafts for satellite communication equipment (made of stainless steel, corrosion-resistant), and drone motor shafts (with diameters ranging from 8 to 22mm, high-speed stability) to meet the dual requirements of precision and strength for small and micro shafts in the aerospace industry.

Precision instrument field

Produce optical instrument focusing shafts (made of brass material with surface roughness Ra ≤ 0.1 μ m) with diameters ranging from 2 to 10mm, calibration shafts for measuring instruments (such as micrometer measuring shafts with diameters ranging from 4 to 8mm and an accuracy of ± 0.0008mm), and clock movement shafts (with diameters ranging from 1 to 3mm and milling slot accuracy of ± 0.001mm) to ensure the measurement accuracy of precision instruments.

3、 Core technical support

Swiss high-precision walking machine equipment

We use high-end Swiss type walking machines such as the Star SV-32 from Switzerland and the Tornos Delta 32 from Japan. The equipment has a maximum spindle speed of 15000rpm and is equipped with 8-12 station milling units. It supports X/Y/Z/C axis linkage and can achieve synchronous machining of turning, milling, drilling, and tapping for shafts with a diameter of ≤ Φ 32mm, with a positioning accuracy of ± 0.0005mm.

High end CNC systems and programming technology

Equipped with Fanuc 31i-B and Siemens 828D CNC systems, it supports macro programming and complex machining path simulation. It can automatically optimize cutting parameters (such as feed rate and speed) for shaft shaped grooves, variable diameter sections, and other structures; Equipped with specialized CAM software (such as GibbsCAM), it can quickly generate turning and milling composite machining paths for shafts with a diameter of ≤Φ 32mm, reducing programming time by 30%.

Micro specialized cutting tools and fixtures

Cutting tools: Adopting Japanese Kyocera and Swiss Sandvik micro cutting tools - the minimum cutting edge radius of the turning tool is 0.01mm (suitable for processing fine shafts of Φ 0.5mm), the minimum milling tool diameter is 0.3mm (suitable for micro groove processing), the tool coating is TiAlN (titanium aluminum nitride), and the wear resistance is improved by 40%;

Fixture: Equipped with customized guide sleeves (inner diameter tolerance ± 0.0005mm) and elastic clamps, special fixtures are replaced for different diameter shafts (such as Φ 2mm, Φ 5mm, Φ 10mm) to ensure that the shafts are not offset or shaken during processing.

Digital Production Management

Introducing MES production execution system to achieve full process digital traceability of orders: After customers place orders for shafts with a diameter of ≤ Φ 32mm, the system automatically matches equipment, cutting tools, and process parameters; Real time collection of equipment operation data during the processing (such as spindle load, processing accuracy); Customers can view order progress and download inspection reports through their mobile devices to achieve "transparent" production.

4、 Frequently Asked Questions (FAQ)

Q: What is the minimum diameter of machinable shaft parts? Can it break through the diameter of 0.5mm?

A: The conventional minimum machining diameter is Φ 0.5mm. If it is necessary to machine ultra-fine shafts with smaller diameters (such as Φ 0.3- Φ 0.4mm), special micro cutting tools and anti vibration technology need to be used. A 3D model can be provided for technical engineers to evaluate the feasibility of the structure and develop a plan (note: shafts with a diameter ≤ Φ 0.4mm need to control the length ≤ 20mm to avoid breakage during machining).

Q: Is there a difference in precision indicators between turning and milling? What is the specific accuracy range?

A: Due to different process characteristics, there are slight differences in accuracy: for turning machining (outer circle, end face), the diameter tolerance is ± 0.001- ± 0.002mm, and the roundness is ≤ 0.0008mm; for milling machining (groove, key, plane), the size tolerance is ± 0.002- ± 0.003mm, and the form and position tolerance (such as parallelism and symmetry) is ≤ 0.003mm. Specific precision parameters can be further optimized according to the purpose of the part.

Q: What technical information is required for customizing shaft parts with a diameter of ≤ Φ 32mm?

A: Suggest providing 2D engineering drawings (indicating diameter tolerances, length, groove depth, thread specifications, surface treatment requirements) or 3D models (STEP, IGS format); If there are special assembly requirements for shafts (such as clearance with other parts), fitting part drawings can be provided to facilitate engineers in optimizing machining accuracy and avoiding assembly lag.

Q: Is there a difference in the machining cycle of shaft parts made of different materials? How long can regular orders be delivered?

A: Due to different material hardness, the processing cycle may vary: for copper and aluminum alloy shafts (easy cutting), small batch orders (1-100 pieces) can be delivered within 5-7 days; Small batch orders for stainless steel and titanium alloy shafts (difficult to cut) can be delivered within 7-10 days; Large batch orders (1000+pieces) can be produced in parallel with multiple machines to shorten the cycle, and the specific delivery time can be negotiated.

Q: Can we provide surface treatment services for shaft components? What are the optional processes?

A: Supporting integrated services of "processing+surface treatment": Metal shafts can be plated (nickel, chromium, gold), passivated (stainless steel rust prevention), anodized (aluminum alloy coloring), sandblasted (matte texture); Plastic shafts can be selected with screen printing or oil spraying, and all surface treatment processes comply with RoHS and REACH environmental standards to meet the needs of different industries.

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |