- Overview

- Related Products

I. Core Advantages

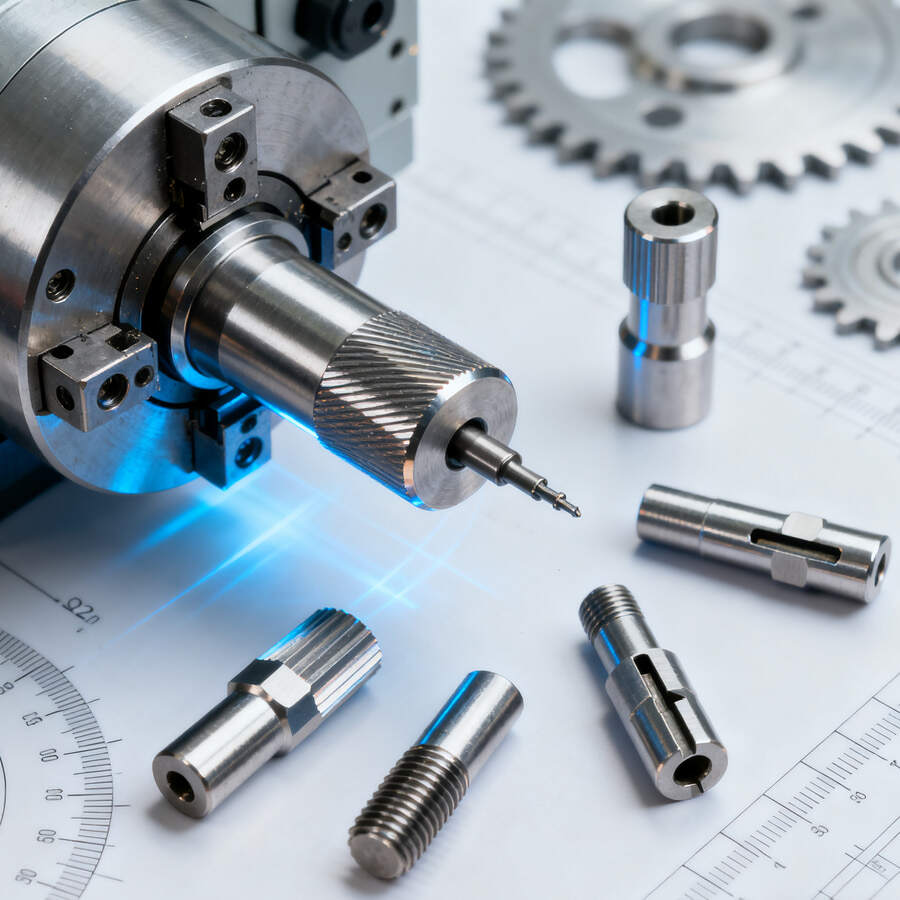

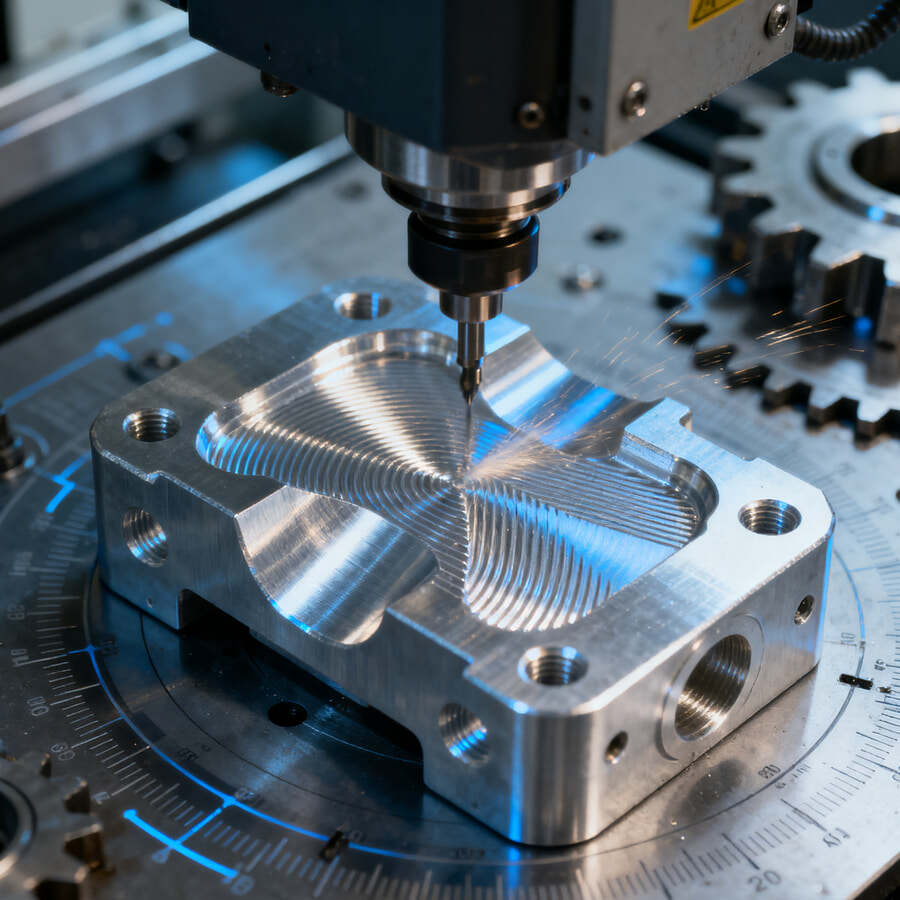

1. Ultra-High Machining Precision: Utilizing a high-precision servo drive system and precision ball screw, positioning accuracy reaches ±0.005mm and repeatability reaches ±0.003mm. This ensures that the dimensional, geometric, and positional tolerances of metal (such as aluminum alloy, stainless steel, and titanium alloy) and plastic (such as POM, PC, and ABS) parts strictly meet design requirements, meeting the assembly needs of precision components.

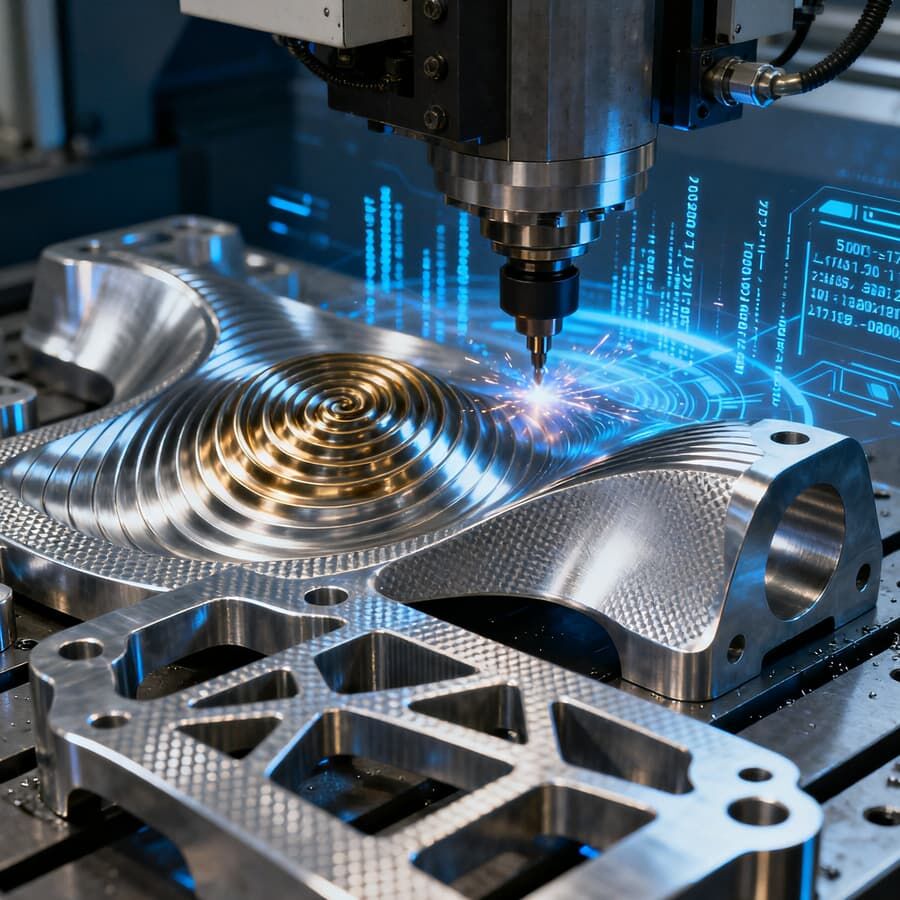

2. Wide Material Compatibility: Tailor-made processing solutions are tailored to the varying physical properties of metals and plastics (e.g., high hardness of metals and thermal deformation of plastics). Metal processing utilizes high-speed carbide tools and a cooling system to minimize thermal deformation. Plastic processing utilizes a dedicated low-temperature cutting process to minimize warping. This allows for stable processing of parts from soft plastics to high-strength alloys.

3. Flexible Customization: We support small-batch trial runs (1-100 pieces) to large-volume production runs (1,000+ pieces). Whether it's complex, custom-shaped parts (such as automotive sensor housings and medical instrument accessories) or standardized precision fasteners, we can quickly disassemble and process them based on customer-provided 2D drawings and 3D models, enabling one-stop customization from "drawing to finished product."

4. Efficient Delivery Guarantee: Equipped with multiple three-axis CNC machining centers, combined with automated loading and unloading devices and an intelligent production scheduling system, our metal part processing efficiency is 30% higher than traditional processes, while plastic part processing cycles are shortened by 20%. Regular orders are delivered within 7-15 days, and urgent orders can be delivered within 48 hours.

II. Core Application Areas

1. Automotive Industry: Customized metal engine mounts, precision gears for transmissions, and plastic interior trim buckles meet the high-strength and wear-resistant requirements of automotive parts.

2. Electronics Industry: Processing of metal connector housings, plastic insulated bases, and precision conductive terminals to meet the miniaturization and high-integration requirements of consumer electronics and industrial control equipment.

3. Medical Industry: Production of titanium alloy surgical instrument accessories (such as hemostat jaws) and ABS plastic medical

4. Equipment housings, meeting medical-grade material hygiene standards and precision assembly requirements.

5. Aerospace: Manufacturing of lightweight aluminum alloy structural parts and high-temperature-resistant PPS plastic sensor housings, balancing strength and lightweight properties.

6. General Machinery: Customized metal bearing housings, plastic drive wheels, and other general accessories for transmission and support applications in various mechanical equipment.

III. Core Technology Support

1. Intelligent CNC System: Equipped with a Siemens 828D / FANUC 0i-MF CNC system, it supports automatic G-code generation and online parameter adjustment, enabling real-time monitoring of the machining process and automatic compensation for tool wear to ensure machining stability.

2. High-Rigidity Machine Structure: The machine bed utilizes a one-piece cast iron casting process, which undergoes an aging treatment to eliminate internal stress and reduce machining vibration. This provides stable support for precision cutting, making it particularly suitable for heavy cutting of hard metal materials.

3. Precision Inspection System: After machining, the machine is equipped with inspection equipment such as a three-dimensional coordinate measuring machine and a two-dimensional imager to fully inspect part dimensions and surface roughness (Ra ≤ 0.8μm for metals and Ra ≤ 1.6μm for plastics) to ensure that every product leaves the factory as qualified.

4. Green Processing: Metal processing utilizes an environmentally friendly cutting fluid circulation system to reduce waste fluid emissions. Waste generated by plastic processing is recyclable and reusable, meeting green production standards.

IV. Frequently Asked Questions (FAQs)

Q: What is the maximum size range of machinable metal and plastic parts? A: The standard machining range is 800mm long × 500mm wide × 400mm high. For larger parts exceeding this size, we offer customized machining solutions. Please consult our technical engineers for details.

Q: Is there a difference in machining accuracy between metal and plastic parts?

A: Due to different material properties, plastic parts may experience slight deformation errors of ±0.01mm due to temperature effects (this has been minimized through process control). Metal parts can maintain a stable accuracy of ±0.005mm. Specific accuracy can be further optimized based on the part's intended use.

Q: What information is required for custom parts?

A: We recommend providing detailed 2D engineering drawings (with tolerances, materials, and surface treatment requirements) or 3D models (such as STEP or IGS formats). If you have special assembly requirements or sample references, these can be provided to facilitate a more precise machining plan.

Q: Do you support surface treatment of parts?

A: Yes! Metal parts can be treated with surface treatments such as anodizing, electroplating, and spray painting. Plastic parts can also be treated with silk screen printing, spray painting, and laser engraving, providing an integrated "processing + post-processing" service, eliminating the need for secondary customer support.

Q: How do you ensure the consistent quality of customized parts?

A: We utilize a three-level quality inspection system consisting of first-article inspection, in-process inspection (sampling every 50 pieces), and full finished product inspection. We also maintain traceability and reproducibility for each batch of parts, ensuring consistent quality throughout mass production.

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |