Wear-Resistant, Low-Friction Copper Alloy CNC Service - Suitable for Custom Bearings, Bushings, and Wear-Resistant Parts

- Overview

- Related Products

I. Core Service Advantages

- Wear-Resistant, Low-Friction Material Properties Extend Part Life: We specialize in processing wear-resistant copper alloys such as tin bronze (QSn6-6-3), aluminum bronze (QAl9-4), and brass (H62/H65). Our friction coefficients are as low as 0.08-0.15 (unlubricated), and our hardness can reach HB150-250, resulting in wear resistance over 40% higher than that of ordinary steel. For high-wear parts like bearings and bushings, the service life of finished products can reach 2-3 times that of parts made of traditional materials, significantly reducing equipment maintenance frequency and costs.

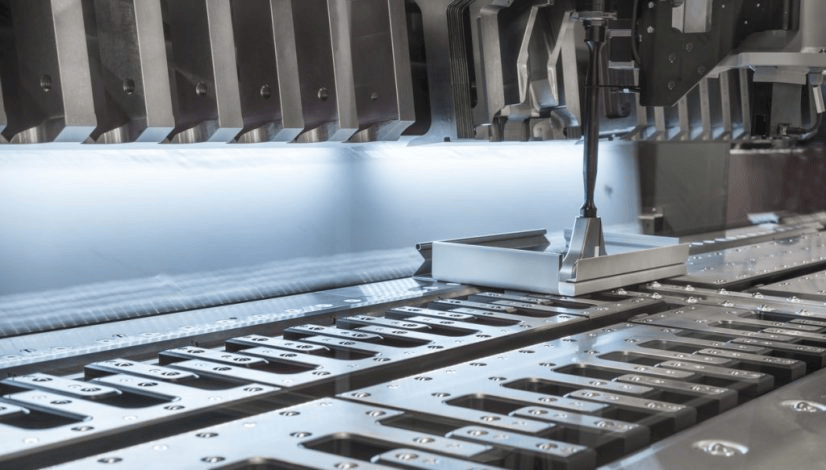

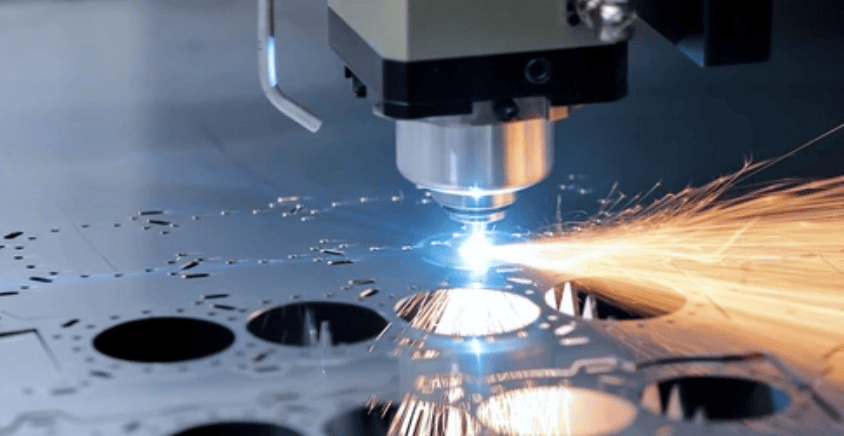

- High-Precision CNC Machining for Precision Assembly: We utilize high-precision CNC milling/lathes with positioning accuracy of ±0.003mm and repeatability of ±0.002mm, enabling precise machining of bearing inner and outer rings, bushing special-shaped holes, and complex contours of wear-resistant parts. Key geometric tolerances are strictly controlled: cylindricity ≤ 0.002mm, perpendicularity ≤ 0.003mm, ensuring clearances with shafts, housings, and other components are kept within 0.005-0.01mm to prevent increased wear due to assembly deviations.

- Customized process adaptation to meet diverse needs: Customized processing solutions are tailored to the characteristics of different copper alloys and part applications. Tin bronze bearings utilize a "rough milling + fine grinding" process, achieving a surface roughness of Ra ≤ 0.2μm, reducing operational friction. Aluminum bronze bushings undergo an aging treatment to increase hardness and enhance wear and impact resistance. Brass wear-resistant parts can be treated with tin or galvanized surface treatments to further optimize corrosion resistance and lubricity.

- Efficient delivery and volume assurance: Supporting small-batch trial production (1-50 pieces) to large-scale mass production (10,000+ pieces), equipped with eight CNC machining centers for parallel production, the processing cycle for standardized parts such as bearings and bushings is 25% shorter than the industry average. A flexible production system has been established, enabling expedited delivery within 48 hours for urgent orders. Standardized fixtures and processes ensure dimensional consistency of parts exceeding 99.5% for mass-produced parts.

II. Core Application Areas

(I) Industrial Machinery

- Transmission System Bearings: We process tin-bronze sliding bearings and self-lubricating bearings for machine tool spindles, reducers, and other transmission components. They operate stably even without lubrication, with friction losses as low as 0.02kW·h/1000h.

- Guide Bushings: We produce aluminum-bronze guide bushings for hydraulic cylinder and pneumatic piston guides. They offer high wear resistance and precision, and can withstand over one million reciprocating cycles without noticeable wear.

(II) Automotive and Transportation

- Engine Wear-Resistant Parts: We produce custom brass valve guides and aluminum-bronze crankshaft bushings that withstand high engine temperatures (200-300°C) and high pressures, ensuring stable powertrain operation. - Chassis Components: We process tin bronze suspension bushings, offering excellent shock absorption and wear resistance, suitable for high-frequency vehicle driving conditions and boasting a service life exceeding 80,000 kilometers.

(III) Textile and Printing Machinery

- Roller Bearings and Bushings: We produce high-precision brass roller bearings with a polished surface (Ra ≤ 0.1μm) to ensure stability during high-speed rotation (1500 rpm) of textile machinery rollers and reduce yarn wear.

- Printing Cylinder Wear Sleeves: We custom-produce aluminum bronze printing cylinder wear sleeves, resistant to ink corrosion and with a surface hardness of HB220 or higher, suitable for the long-term continuous operation requirements of printing presses.

(IV) Medical Devices

- Surgical Instrument Wear Parts: We process tin bronze surgical instrument spherical bearings. Their low friction ensures precise and controllable operation, and their surface passivation meets medical-grade hygiene standards (easy to clean, no blind spots).

- Diagnostic Equipment Bushings: We produce brass guide bushings for diagnostic instruments. Precision fit ensures the movement accuracy of equipment testing components, with an error of ≤ 0.002mm. III. Core Technology Support

- High-Precision Machining Equipment: Equipped with a Japanese FANUC α-T21iFb lathe and a German DMG DMU 35 CNC machining center, with a maximum spindle speed of 12,000 rpm and a rapid traverse speed of 48 m/min, they support integrated milling, turning, and drilling of complex copper alloy parts, ensuring precision and efficiency.

- Specialized Tools and Processes: Utilizes carbide-coated tools (TiAlN coating), with optimized cutting edge angles (rake angle of 12°-15°) tailored to the sticking characteristics of copper alloys. A high-pressure coolant system (60 bar) reduces chip adhesion and improves surface quality. Honing is employed for precision structures such as bearing bores, achieving cylindricity control within 0.001 mm. - Quality Inspection System: Before processing, the copper alloy's material composition (spectrographic analysis) and mechanical properties (hardness tester testing) are verified. During processing, every 50 pieces are sampled for key dimensions. After processing, comprehensive testing is performed using a coordinate measuring machine (accuracy ±0.0005mm), a roughness tester, and a friction and wear testing machine to ensure that the finished product meets wear resistance and precision standards.

- Digital Production Management: The introduction of the MES production execution system enables real-time tracking of order progress, equipment status monitoring, and process parameter traceability. Customers can access part processing progress and inspection reports through the system, ensuring transparency and controllability of the production process.

Fourth, Frequently Asked Questions (FAQs)

- Q: What copper alloy grades can be processed? Are there differences in wear resistance between grades?

A: We routinely process tin bronze (QSn6-6-3, friction coefficient 0.08-0.12), aluminum bronze (QAl9-4, hardness HB200-250), and brass (H62/H65, moderate wear resistance). Custom processing is available for special grades (such as phosphor bronze QSn4-3). The wear resistance of different grades differs primarily in hardness and friction coefficient, and we can recommend the appropriate material based on the part's operating conditions.

- Q: What is the machining accuracy and surface roughness achieved for bearings and bushings?

A: The inner/outer ring diameter tolerance for bearings is ±0.002-±0.003mm, with cylindricity ≤0.002mm; the inner diameter tolerance for bushings is ±0.003mm, with perpendicularity ≤0.003mm. Surface roughness is typically Ra ≤0.4μm, and precision parts can achieve Ra ≤0.1μm, meeting high-speed, low-friction requirements.

- Q: What is the lead time for custom copper alloy wear-resistant parts? Can lead times be shortened for bulk orders?

A: Small orders (1-50 pieces) have a delivery time of 5-7 days. Large orders (1,000+ pieces) can be shortened to 7-10 days by using multiple machines for parallel production. The specific delivery time is negotiable based on order volume and part complexity. Urgent orders can be expedited within 48 hours.

- Q: Does surface treatment affect the dimensional accuracy of copper alloy parts? What surface treatment processes are available?

A: A certain allowance is reserved before surface treatment (for example, 0.005-0.008mm for tin plating). After treatment, the dimensional tolerance change is ≤±0.002mm, which does not affect assembly accuracy. Optional processes include tin plating, galvanizing, passivation, polishing, and sandblasting, depending on requirements such as rust prevention, lubrication, and aesthetics.

- Q: Can you provide trial production of samples? Will mass production be initiated after the samples are qualified?

A: We support trial production of samples! We can produce 1-3 samples first. After the customer confirms the wear resistance, dimensional accuracy, and appearance, we can start mass production. The sample trial production cycle is 3-5 days. During the trial production process, the process parameters can be adjusted according to the feedback to ensure that the final product meets expectations.

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |