One-stop service for high-strength aluminum alloy CNC milling/turning, anodizing, sandblasting, and other surface treatments.

- Overview

- Related Products

Services

I. Core Service Advantages

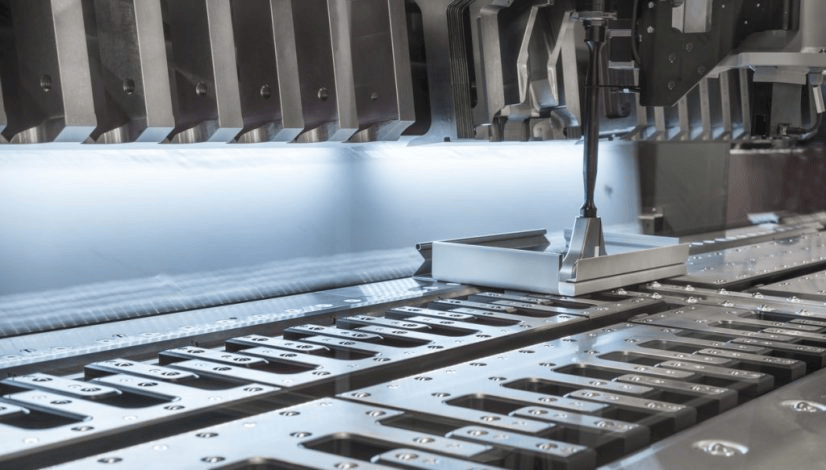

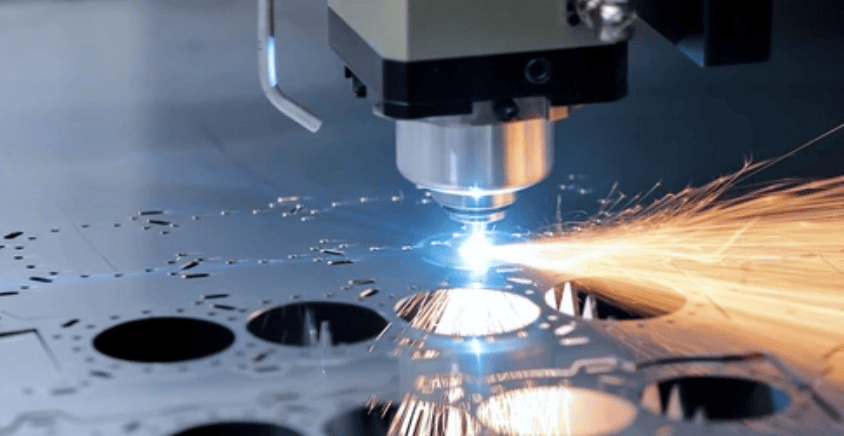

1. Precision machining of high-strength aluminum alloys, balancing rigidity and precision.

Targeting the specific characteristics of high-strength aluminum alloys such as 6061-T6, 7075-T6, and 2A12 (tensile strength ≥380MPa), we utilize high-rigidity CNC equipment and specialized tools to achieve integrated milling and turning. Milling flatness is ≤0.005mm/100mm, while turning tolerance is ±0.002mm. This effectively addresses the issues of burr generation and rapid tool wear associated with high-strength aluminum alloy machining. We also support machining of complex structures, such as polyhedrons, deep cavities, and special-shaped contours, meeting the structural and performance requirements of high-precision parts.

2. One-stop integrated surface treatment, eliminating the need for multiple stages of integration.

This platform integrates surface treatment processes such as anodizing (natural, black, and colored), sandblasting (fine, coarse, and matte), brushing, spraying, and passivation. After processing, the product can be directly transferred to the surface treatment stage, eliminating the need for customers to re-interact with third-party suppliers. Through collaborative process optimization, the matching of surface treatment and processing dimensions is ensured. For example, the dimensional tolerance of parts after anodizing can be controlled within ±0.003mm, eliminating the dimensional deviations and quality risks associated with traditional multi-stage processes.

3. Strong process adaptability to meet diverse surface requirements

- Anodizing: Creates a uniform oxide layer with a thickness of 5-20μm, improving the corrosion resistance (salt spray test ≥480 hours) and wear resistance of high-strength aluminum alloys, making it suitable for parts exposed to outdoor and humid environments;

- Sandblasting: Adjusts the grit size (80-320 mesh) to create varying matte finishes, concealing machining marks and enhancing part consistency. This process is commonly used for device casings and panels;

- Brushing: Creates a uniform, straight texture, enhancing the visual quality of parts, making it suitable for exterior components in consumer electronics and high-end devices;

- Customizable Combination Processes: Supports combination processes such as "sandblasting + anodizing" and "brushing + coloring," meeting customer needs for both appearance and performance.

4. A closed-loop quality control system ensures product consistency throughout the entire process.

A four-level quality control system has been established: "Material testing - Processing monitoring - Surface treatment inspection - Finished product full inspection." This system verifies the composition and mechanical properties of high-strength aluminum alloys before processing; monitors cutting parameters and dimensional accuracy in real time during processing; and inspects film thickness, adhesion, and color difference after surface treatment. Finished products are fully inspected using equipment such as coordinate measuring machines and gloss meters. Complete quality reports are maintained for each batch of parts to ensure consistency and stability during mass production.

II. Core Application Areas

1. New Energy Vehicles

Customized high-strength aluminum alloy battery pack brackets (milling, anodizing for rust prevention), motor housings (milling and lathing, sandblasting and anodizing for corrosion resistance), and lightweight chassis components (7075-T6 material, milling complex structures, and surface passivation treatment) meet the high-strength and lightweight requirements of automotive parts.

2. Aerospace Auxiliary Equipment

We manufacture high-strength aluminum alloy aviation ground equipment frames (6061-T6 material, milled polyhedron structure, anodized), drone fuselage components (turned special-shaped shafts, sandblasted for weight reduction and noise reduction), and satellite communication equipment housings (2A12 material, milled deep cavity structure, brushed and anodized for enhanced appearance and weather resistance), meeting the stringent performance and weight requirements of the aerospace industry.

3. Industrial Automation and Equipment

We process high-strength aluminum alloy robotic arm joints (milled high-precision holes, anodized for wear resistance), equipment guide rails and sliders (turned external diameter, sandblasted to reduce friction), and sensor mounts (milled complex contours, passivated for rust prevention), ensuring the operating accuracy and service life of automated equipment.

4. Consumer Electronics and Smart Devices

We manufacture custom high-strength aluminum alloy mobile phone frames (7075-T6 material, milled thin-wall structure, brushed and anodized), smart wearable device housings (turn-milling composite processing, sandblasting and coloring), and laptop stands (6061-T6 material, milled hollow structure, matte anodized) to meet the demand for lightweight, high-strength, and aesthetically pleasing parts in consumer electronics.

5. Medical Devices

We manufacture high-strength aluminum alloy medical cart frames (milled assembly holes, anodized for antibacterial treatment), diagnostic instrument panels (turned with rounded edges, sandblasted for anti-glare), and surgical instrument accessories (2A12 material, milled with precision structure, passivated for rust prevention), meeting medical-grade hygiene standards and safety requirements.

III. Core Technology Support

1. High-Precision CNC Machining Equipment

Equipped with CNC milling and turning machines from DMG MORI of Germany and FANUC of Japan, the system boasts a maximum spindle speed of 15,000 rpm and a rapid traverse speed of 48 m/min, supporting the machining of complex curved surfaces and high-precision holes. For high-strength aluminum alloys, the system utilizes carbide-coated tools (such as TiAlN coatings), increasing cutting efficiency by 30% and extending tool life by 25%.

2. Core Surface Treatment Processes

- Anodizing: Utilizes a sulfuric acid hard anodizing process, equipped with a fully automated anodizing production line to ensure uniform oxide layer formation. A constant temperature control system (±1°C) prevents deformation of the high-strength aluminum alloy during oxidation.

- Sandblasting: Utilizes automated sandblasting equipment with controllable pressure (0.3-0.8 MPa) and customized fixtures to ensure 100% surface coverage and texture consistency ≤ ΔE2.0.

- Process Integration Technology: After processing, parts undergo a dedicated cleaning process (degreasing, deoiling, and passivation pretreatment) to ensure a surface free of oil and impurities, enhancing the adhesion of the surface treatment layer (cross-cut test ≥ 5B).

3. Digital Collaborative Management

Introducing an integrated CAD/CAM/MES system: 3D modeling and machining path planning for high-strength aluminum alloy parts are accomplished using UG and Mastercam software. Leveraging the MES system, order progress tracking, equipment status monitoring, and traceability of machining and surface treatment process parameters are achieved. Customers can view order production milestones and quality inspection data in real time, achieving a transparent and efficient one-stop service process.

4. Customized Process R&D Capabilities

We have a professional process R&D team that can conduct process testing and optimization based on specific customer needs (such as ultra-high salt spray resistance anodizing and custom color sandblasting). For example, for new energy vehicle battery pack parts, we have developed a combined "sandblasting + hard anodizing" process that can withstand salt spray testing for over 1,000 hours, meeting the demands of extreme environments.

IV. Frequently Asked Questions (FAQs)

1. Q: What high-strength aluminum alloy grades can be processed? Can you process special aluminum alloy grades?

A: We routinely process mainstream high-strength aluminum alloys such as 6061-T6, 7075-T6, 2A12, and 5052-H32. For special grades (such as 7050 and 6082), please provide material samples and technical specifications in advance. We will conduct process testing to assess the feasibility of processing and surface treatment.

2. Q: What is the total turnaround time for part processing and surface treatment? Does the different surface treatment processes significantly affect turnaround time?

A: For regular small-batch orders (1-50 pieces), the turnaround time is 7-12 days. Large-batch orders (1,000+ pieces) can be shortened to 10-15 days through multi-line parallel production. The turnaround times for different surface treatment processes vary: anodizing (3-5 days), sandblasting (1-2 days), and wire drawing (2-3 days). The combined process times are based on the actual process steps and can be negotiated based on order volume.

3. Q: Will the dimensions of the parts change after surface treatment? How can assembly accuracy be guaranteed?

A: Anodizing produces a 5-20μm oxide layer. A corresponding dimensional margin is reserved during processing (e.g., if the finished product diameter is Φ10mm, the diameter is controlled to Φ9.98-Φ9.99mm during processing). Physical surface treatments such as sandblasting and brushing have a dimensional impact of ≤0.002mm, which is negligible. By retaining margins and conducting a full inspection, we ensure that the surface-treated part dimensions meet assembly requirements, with a tolerance of ±0.003mm.

4. Q: Can you provide sample testing of the surface treatment? Will we confirm the results before mass production?

A: We support sample testing! We can first produce 1-3 parts and complete the specified surface treatment (e.g., anodizing, sandblasting). After the customer confirms the appearance and performance (e.g., film thickness, adhesion), we can start mass production. Sample testing takes 3-5 days. During the testing process, we can adjust process parameters based on feedback to ensure the final product meets expectations.

5. Q: Is the price of a one-stop service more competitive than hiring separate processing and surface treatment vendors?

A: Yes! By synergizing and integrating machining and surface treatment processes, we eliminate intermediate transfer costs and quality risks, reducing overall prices by 10%-15% compared to separate collaborations. This also reduces customer interaction, shortens delivery cycles, improves service efficiency and quality stability, and offers a more cost-effective solution.

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |