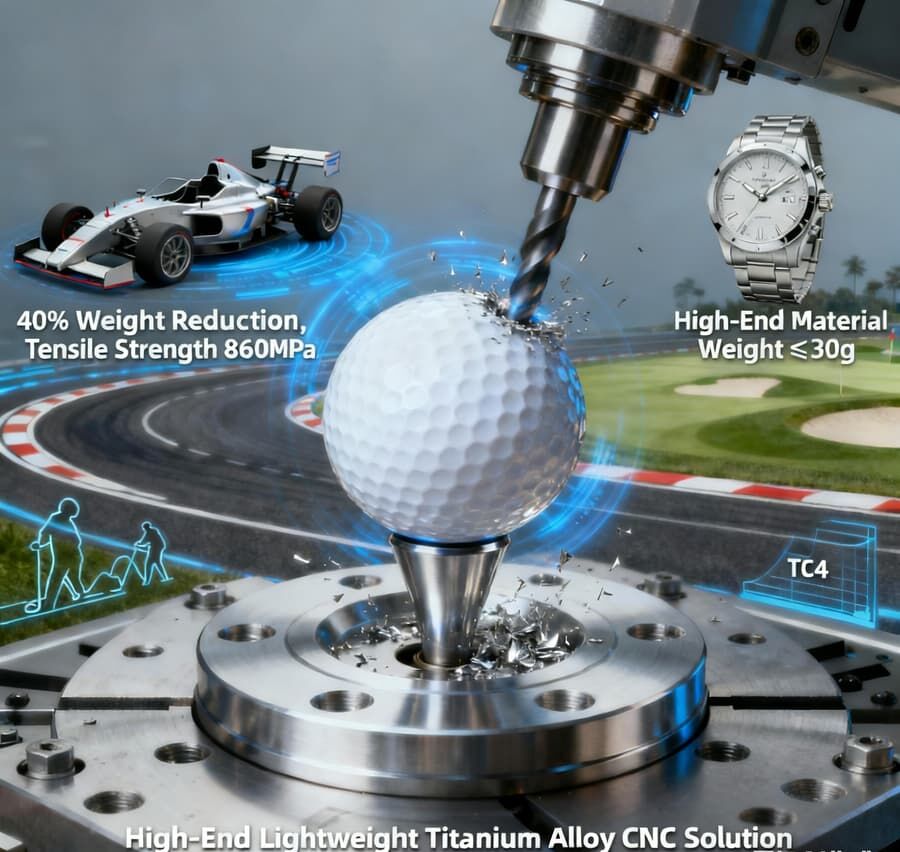

High-End Lightweight Titanium Alloy CNC Solutions - Custom Parts for Racing Cars, Golf Heads, and High-End Consumer Products

- Overview

- Related Products

Customized Parts

I. Core Service Advantages

1. Perfect Balance of Lightweight and High Strength

We specialize in processing high-end titanium alloys such as TC4 (Ti-6Al-4V), TC11, and GR5. These materials boast a density of only 4.5g/cm³ (approximately half that of steel) but a tensile strength of 860-1100MPa, resulting in a strength-to-weight ratio far exceeding that of aluminum alloys and stainless steel. Through integrated CNC precision milling/turning, we reduce part weight by 30%-50% while increasing structural strength by 20%-40%. This perfectly meets the core requirements of "weight reduction and speed improvement" for racing cars, "precise weight balance" for golf heads, and "lightweight and premium" for high-end consumer products.

2. Precision Customization of Complex Structures, Breaking Through Process Bottlenecks

For special-shaped parts in three major application areas (such as hollowed-out racing chassis frames, complex curved surfaces in golf heads, and irregular accessories for luxury goods), we utilize five-axis CNC machining with positioning accuracy of ±0.002mm and repeatability of ±0.001mm. This system supports machining complex features such as thin walls (down to 0.8mm), deep cavities (aspect ratio of 10:1), and irregularly shaped holes. Surface profile tolerances are ≤±0.003mm, and surface finishes are Ra ≤0.4μm, ensuring the reproduction of design details.

3. Exclusive Titanium Alloy Processing Technology Ensures Stable Quality

To address the processing challenges of titanium alloys due to their low thermal conductivity and prone to tool sticking, three core processes have been customized:

- Low-Temperature Cutting Technology: Equipped with a -15°C cold air cooling system, this reduces thermal stress during machining and prevents warping in thin-walled parts;

- High-Pressure Internal Cooling: Cooling pressures reach 100 bar, rapidly removing chips and preventing tool wear (extending tool life by 35%);

- Aging Treatment: Post-processing, a 500-600°C vacuum aging treatment enhances the fatigue strength of titanium alloy parts, achieving a fatigue life of over 100,000 cycles for racing parts.

4. Full-Scenario Customization and Leading Delivery Efficiency

Supporting both small-batch customization (1-20 pieces) and medium-batch production (50-500 pieces), we can rapidly respond to requests for racing car parts, golf head prototypes, and limited-edition high-end consumer goods, including 2D drawings and 3D models (in STEP/IGS/X_T formats), with a process and disassembly cycle time reduced to 24 hours. Equipped with three five-axis machining centers for parallel production, regular order delivery is 7-12 days, while urgent racing parts orders can be delivered within 48 hours.

II. Core Application Areas

(I) Customized Parts for Racing

1. Chassis and Suspension Components

- Lightweight Titanium Chassis Frame: Milled from a TC4 titanium alloy hollow structure, it reduces weight by 40% compared to a steel chassis while increasing torsional rigidity, making it suitable for Formula One and modified sports cars.

- Suspension Links and Shock Absorber Brackets: Integrated turning and milling, anodized (natural/blue) with a tensile strength of ≥900 MPa, ensuring structural stability under extreme operating conditions.

2. Powertrain and Transmission Parts

- Titanium Exhaust System Accessories: GR5 titanium exhaust pipe flanges and connecting pipes are machined for high-temperature resistance (above 600°C) and corrosion resistance, reducing weight by 30% and lowering the vehicle's center of gravity.

- Lightweight Transmission Gears: Five-axis milling of complex tooth profiles achieves ISO Class 5 accuracy, improving meshing efficiency by 5%, meeting the high-speed transmission requirements of racing cars.

(II) Customized Golf Head Parts

1. Head Body and Counterweight

- Titanium Head Frame: A hollow structure is milled from TC11 titanium alloy with a wall thickness of 1.2-2mm, weighing 150-200g, improving energy transfer efficiency by 8% during impact.

- Adjustable Counterweights: TC4 titanium alloy counterweight spikes are machined (available in weights of 5-20g) and sandblasted to accommodate customized swing styles.

2. Shaft Connection Components

- Titanium Alloy Head Sleeve: Precision-turned tapered structure with a tolerance of ±0.002mm ensures a secure connection between the shaft and the head, reducing energy loss during impact.

(III) Customized Parts for High-End Consumer Products

1. Luxury Accessories

- Titanium Alloy Watch Cases/Straps: Five-axis milling of complex curved surfaces, PVD-plated black/rose gold finish, 40% lighter than stainless steel cases for greater comfort;

- High-End Luggage Hardware: TC4 titanium alloy pull rods and buckles are machined for high strength and resistance to deformation. A combination of sandblasting and brushing enhances the finish, making them suitable for custom luxury luggage brands.

2. Smart Wearables and High-End Tools

- Titanium Alloy Smartwatch Middle Frame: Milled thin-walled hollow structure, weighing ≤30g, compatible with wireless charging and waterproof (IP68 rating);

- High-End Outdoor Knife Handles: Turned and milled with a non-slip texture, made of impact-resistant TC4 material, suitable for use in extreme outdoor environments.

III. Core Technology Support

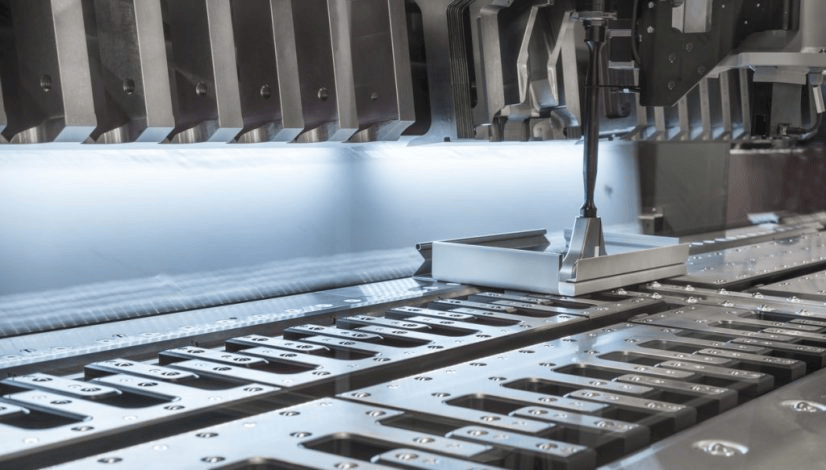

1. High-End Five-Axis CNC Machining Equipment

Equipped with German DMG MORI NTX 2000 and Japanese FANUC α-500iA five-axis machining centers, these machines boast a maximum spindle speed of 20,000 rpm, a rapid traverse rate of 60 m/min, and support NURBS curve interpolation, enabling precise fitting of complex surfaces such as racing car parts and golf heads. The equipment is equipped with a dedicated titanium alloy machining module that monitors cutting load and temperature in real time and automatically adjusts parameters.

2. Titanium Alloy-Specific Tools and Fixtures

- Tools: Utilizes Swiss Sandvik WC-Co ultra-fine-grain carbide tools (0.01mm cutting edge radius) and Japanese Sumitomo Electric CBN tools. The cutting edge angle (rake angle of 10°-15°) is optimized for titanium alloy machining to reduce cutting forces.

- Fixtures: Customized vacuum chucks and spring chucks utilize a multi-point support design for thin-walled titanium alloy parts, preventing deformation during machining and achieving a positioning accuracy of ±0.001mm.

3. Full-Process Quality Control System

- Material Testing: Before processing, titanium alloy composition (such as the Al and V content in TC4) is verified using a spectrometer to ensure material purity.

- Process Monitoring: After each process, laser diameter measuring instruments and 2D imaging instruments are used for random dimensional inspection.

- Finished Product Inspection: Full-dimensional inspection is performed using a three-dimensional coordinate measuring machine (accuracy ±0.0005mm) and a blue light scanner, along with mechanical properties tested using a tensile testing machine, to ensure that the finished product meets design standards.

4. Surface Treatment and Process Synergy

Integrating high-end surface treatment processes such as PVD coating, anodizing, sandblasting, and brushing, seamlessly integrates processing and finishing. For example, golf club heads utilize a "sandblasting + spot polishing" process, racing car parts utilize an "anodizing + laser marking" process, and high-end consumer products utilize a "PVD color coating + vacuum oil sealing" process, ensuring a balanced balance of performance and appearance.

IV. Frequently Asked Questions (FAQs)

1. Q: What titanium alloy grades can be processed? What applications are different grades suitable for? A: We process standard materials such as TC4 (GR5, general-purpose, suitable for racing, golf, and consumer goods), TC11 (high-strength, suitable for racing powertrain components), and GR2 (pure titanium, corrosion-resistant, suitable for high-end consumer goods). Customized process testing is available for special materials (such as TC21 and BT20). Material parameters and design requirements must be provided in advance.

2. Q: What is the machining accuracy and surface roughness achieved for titanium alloy parts?

A: Dimensional tolerances are ±0.002-±0.005mm, flatness ≤0.003mm/100mm, and coaxiality ≤0.002mm. Surface roughness is typically Ra ≤0.4μm, reaching Ra ≤0.1μm after polishing and Ra 1.2-2.0μm (matte finish) after sandblasting.

3. Q: What is the lead time for custom racing/golf parts? Can you meet urgent event requirements?

A: Regular small-batch orders (1-10 pieces) have a delivery time of 7-10 days. Emergency racing parts (such as race repair parts) can be delivered within 48 hours. Part complexity and production capacity arrangements must be discussed in advance to ensure the race schedule is not impacted.

4. Q: What surface treatments are supported for titanium alloy parts? Will this affect dimensional accuracy?

A: We support PVD coating (film thickness 0.5-5μm), anodizing (film thickness 5-15μm), sandblasting, brushing, etc. During processing, we reserve a dimensional margin for the surface treatment (e.g., 0.003-0.005mm for PVD coating) to ensure that the finished dimensions meet assembly requirements, with a tolerance of ≤±0.002mm.

5. Q: For custom high-end consumer parts, can we provide trial samples? Will we then proceed to mass production after confirming the results?

A: We support trial samples! We can produce 1-3 samples first, and then initiate mass production after the customer confirms the appearance, dimensions, and texture. The sample trial production cycle is 5-7 days. During the trial production process, the processing and surface treatment process can be adjusted according to the feedback to ensure the final product

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |