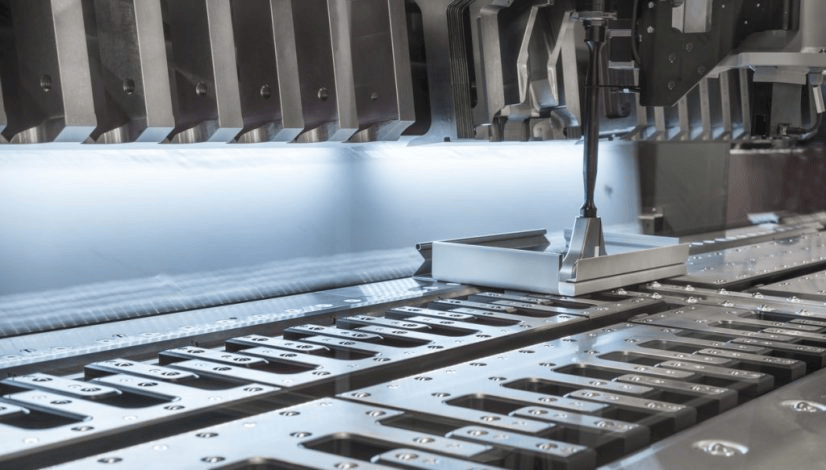

CNC precision machining of stainless steel structural parts - high strength and durability, suitable for automation equipment and industrial machinery.

- Overview

- Related Products

I. Core Service Advantages

1. High-strength materials, leading durability

We specialize in machining mainstream stainless steel materials such as 304, 316, and 440C. Finished products achieve tensile strengths of 520-1300 MPa, yield strengths ≥205 MPa, and hardnesses ranging from HRC15-58 (depending on the model). Through integrated CNC milling/turning, components avoid weaknesses caused by welding and splicing, extending the service life of components by over 50% compared to traditional processes. They can withstand the high-frequency shocks of automated equipment and the heavy loads of industrial machinery, reducing ongoing maintenance and replacement costs.

2. Precision machining control to meet equipment assembly requirements

Utilizing high-precision CNC machining centers with positioning accuracy of ±0.003mm and repeatability of ±0.002mm, we can process complex stainless steel components (such as polyhedral frames, deep-cavity housings, and special-shaped connectors). Key geometric tolerances are strictly controlled: flatness ≤ 0.005mm/100mm, coaxiality ≤ 0.004mm, ensuring precise assembly with components such as motors and guide rails in automated equipment, preventing operational delays or equipment damage due to dimensional deviations.

3. Optimized corrosion and wear resistance for harsh environments

Customized processing tailored to the characteristics of stainless steel: 316 stainless steel parts undergo passivation treatment and can withstand salt spray tests for over 1000 hours, making them suitable for humid, acidic, and alkaline industrial environments. 440C stainless steel parts undergo low-temperature aging treatment, increasing their surface hardness to HRC55-58 and improving wear resistance by 40% compared to ordinary stainless steel, making them suitable for transmission friction components in automated equipment. Surface finishing options include polishing (Ra ≤ 0.2μm) and sandblasting (matte finish), ensuring both corrosion resistance and aesthetic requirements are met.

4. Balancing both mass production and customization, with stable delivery efficiency

We support small-batch trial runs (1-50 pieces) to large-volume production (1,000+ pieces). Equipped with multiple CNC machines for parallel production, we reduce the processing cycle for conventional stainless steel structural parts by 20%-30% compared to the industry average. We can quickly respond to non-standard customization requests for automation equipment and industrial machinery, providing 2D drawings/3D models (STEP/IGS formats) and a full-process service from process breakdown to finished product delivery. Urgent orders can be delivered within 72 hours.

II. Core Application Areas

1. Automation Equipment

- Robotic Arm Structural Components: 304 stainless steel robotic arm bodies and joint connectors are machined. High strength ensures load capacity (a single arm can bear up to 50-200kg), and precision machining ensures precise coordination of multiple joints.

- Conveyor System Components: Stainless steel conveyor belt supports and guide rails are manufactured. The wear-resistant 440C material guide rails offer a service life exceeding 100,000 hours and are suitable for automated production lines in industries such as food and electronics.

- Sensor Mounts: High-precision mounting cavities are milled from 316 stainless steel, providing waterproof and corrosion resistance for automated testing equipment used outdoors or in humid environments.

2. Industrial Machinery

- Machine Tool Structural Parts: We manufacture stainless steel machine tool beds and worktables, offering superior overall rigidity and a 30% increase in vibration attenuation compared to cast iron parts, ensuring stable machining accuracy.

- Printing/Packaging Machinery Components: We manufacture stainless steel roller shafts and gearbox housings. The 316 material resists ink corrosion, and the surface polishing reduces material adhesion, improving equipment efficiency.

- Metallurgical/Chemical Machinery Accessories: We customize stainless steel high-temperature-resistant brackets and pipe connection flanges, capable of withstanding temperatures of 300-500°C and chemical corrosion, suitable for extreme industrial conditions.

3. New Energy Equipment

- Energy Storage Equipment Frames: We mill 304 stainless steel energy storage battery cabinet frames, offering high strength, resistance to deformation, and the ability to support the weight of multiple layers of battery modules.

- Photovoltaic Equipment Components: We manufacture stainless steel tracking system slewing brackets, offering strong weather resistance, suitable for long-term outdoor exposure to sunlight and rain, ensuring precise angle adjustment of photovoltaic panels. 4. Medical Industry Machinery

- Medical Equipment Racks: We manufacture 316L stainless steel diagnostic instrument racks with an electrolytically polished surface that meets medical-grade hygiene standards (easy to clean, no blind spots).

- Surgical Instrument Transmissions: We process 440C stainless steel surgical instrument transmission shafts. High precision and wear resistance ensure precise and controllable surgical operations.

III. Core Technology Support

1. High-Precision CNC Machining Equipment

Equipped with German DMG DMU 50 and Japanese FANUC α-D21LiB5 vertical machining centers, they boast a maximum spindle speed of 18,000 rpm and a rapid traverse speed of 60 m/min, supporting five-axis simultaneous machining of complex stainless steel components. To address the high hardness of stainless steel, we utilize a highly rigid machine bed (one-piece cast iron with three-stage aging treatment) to minimize precision deviations caused by machining vibration.

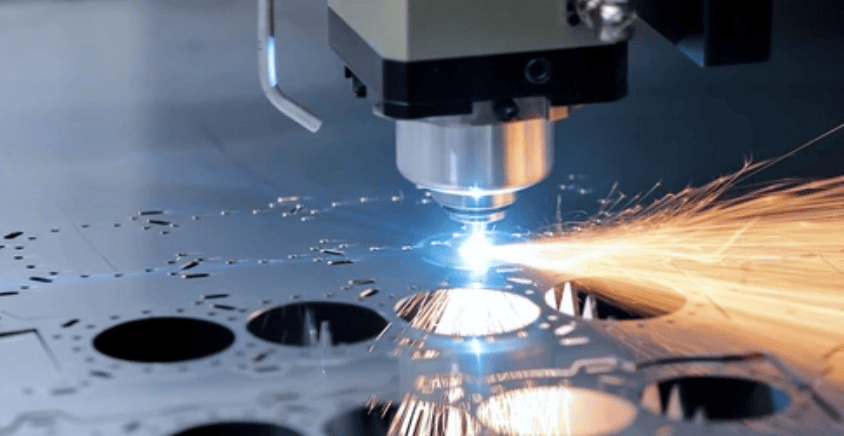

2. Specialized Tools and Cutting Processes

- Tools: Use Swiss Sandvik and Japanese Kyocera carbide coated tools (TiAlN/TiCN coating), which offer a 35% longer tool life than standard tools and can efficiently cut high-strength stainless steels such as 440C.

- Cutting Process: A high-pressure internal coolant system (70 bar) quickly dissipates cutting heat and prevents tool sticking during stainless steel machining. A layered milling process is used for deep cavity structures, with each layer cutting to a depth of 0.1-0.3mm to ensure cavity wall verticality and surface finish.

3. Full-Process Quality Inspection System

- Pre-processing: Verify stainless steel material composition (spectroscopic analysis) and mechanical properties (hardness tester, tensile testing machine testing);

- During processing: Real-time monitoring of cutting parameters via the CNC system, with key dimensions sampled every 50 pieces;

- Post-processing: Full-dimensional inspection using a coordinate measuring machine (accuracy ±0.001mm), combined with equipment such as a roughness tester and salt spray tester, to ensure that finished products meet standards for strength, corrosion resistance, and precision.

4. Digital Production Management

The introduction of an MES production execution system enables real-time tracking of order progress, equipment status monitoring, and process parameter traceability. Customers can access the processing progress and inspection reports of stainless steel structural parts through the system, ensuring transparency of the production process and controllable delivery cycles.

IV. Frequently Asked Questions (FAQs)

1. Q: What stainless steel grades can be processed? What are the differences in the application scenarios of different grades?

A: We process standard grades of 304 (general-purpose, corrosion-resistant, suitable for automation equipment frames), 316 (stronger acid and alkali resistance, suitable for the chemical and medical industries), and 440C (high strength and wear resistance, suitable for transmission friction components). We also offer customized processing solutions for special grades (such as 316L and 2205 duplex steel), but material specifications must be confirmed in advance.

2. Q: What is the machining accuracy and surface roughness of stainless steel structural parts?

A: Dimensional tolerances can be controlled within ±0.003-±0.005mm, flatness ≤0.005mm/100mm, and coaxiality ≤0.004mm. Surface roughness is typically Ra ≤0.8μm, reaching Ra ≤0.2μm after polishing, and Ra 1.6-3.2μm (matte finish) after sandblasting.

3. Q: How can we ensure product consistency in mass-produced stainless steel structural parts?

A: Through standardized process flows (standardized tools, cutting parameters, and fixtures), equipment precision compensation (calibrating machine tool positioning accuracy every shift), a three-level quality inspection system (first article, patrol inspection, and full inspection), and integrated MES system traceability for each batch of processing data, we ensure that the dimensional deviation of batch products is ≤±0.002mm, with a consistency of over 99.5%.

4. Q: Can stainless steel structural parts be subjected to subsequent surface treatment? What are the available processes?

A: Yes! Optional processes include: passivation (to improve corrosion resistance), electropolishing (medical-grade finish), sandblasting (matte finish), chrome/nickel plating (to enhance wear resistance), and laser marking (to identify information). Single or combined processes can be selected depending on the application scenario. The dimensional tolerance after surface treatment is ≤±0.003mm.

5. Q: What information is required for custom stainless steel structural parts? What is the lead time?

A: 2D engineering drawings (with dimension tolerances, materials, and surface treatment requirements) or 3D models (STEP/IGS format) are required. Small orders (1-50 pieces) are delivered in 7-10 days, large orders (1,000+ pieces) in 12-15 days, and urgent orders can be delivered within 72 hours (limited to simple structures).

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |