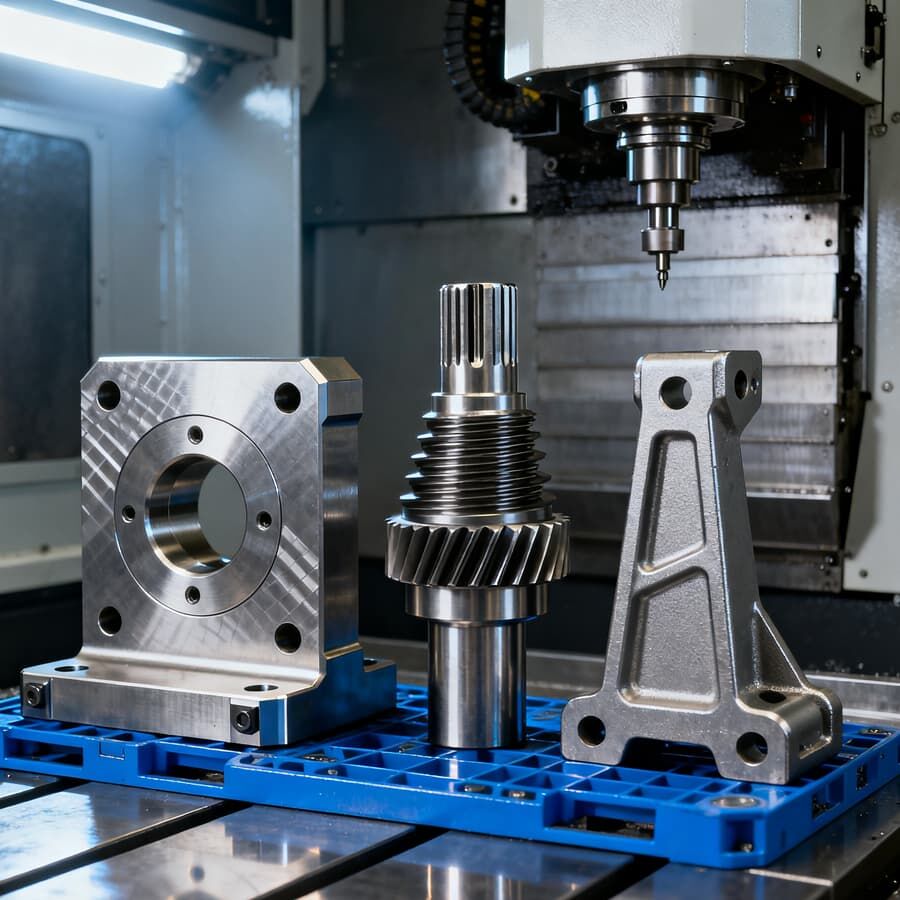

CNC Machining of High-Load Structural Parts and Fixtures - Customized Carbon Steel/Alloy Steels, Such as 4140, 4340, and Q235

- Overview

- Related Products

I. Core Service Advantages

- Precision machining of high-strength materials for superior load-bearing performance: We specialize in machining carbon steels and alloy steels such as 4140 (tensile strength ≥1000MPa after quenching and tempering), 4340 (yield strength ≥860MPa), and Q235 (tensile strength 375-500MPa). Our "rough milling + fine milling + aging" process ensures the overall rigidity and deformation resistance of high-load structural parts. For load-bearing components (such as equipment brackets and fixture bodies), post-machining deflection is ≤0.05mm/m, and they can withstand long-term impact loads (impact energy ≥50J), extending their service life by over 60% compared to parts machined from ordinary steel. - Integrated manufacturing of complex fixtures and structural components improves assembly efficiency: This system supports complex structural machining of high-load fixtures (such as welding fixtures and tooling fixtures) and large structural components (such as machine tool beds and construction machinery supports). It can complete multi-faceted surfaces, special-shaped grooves, stepped countertops, and other features in a single process, reducing clamping times from the traditional 5-8 to 1-2 times. Cumulative positioning error is controlled within ±0.005mm. Fixture positioning accuracy reaches ±0.003mm, ensuring consistent workpiece clamping and improving downstream production efficiency.

- Material-specific process adaptation balances efficiency and quality: Customized processing solutions are tailored to the characteristics of different carbon steels and alloy steels. 4140/4340 alloy steel utilizes a "quenching and tempering pretreatment + cryogenic cutting" process to avoid tool wear caused by work hardening. Q235 carbon steel utilizes a high-speed milling process (feed speed 800mm/min) with dedicated chipbreakers, increasing processing efficiency by 30%. It also supports subsequent heat treatments such as quenching and carburizing. The hardness of 4140 after surface quenching can reach HRC50-55, meeting high wear resistance requirements.

- Large-Size and Batch Processing Capabilities, Stable and Controllable Delivery: Capable of processing large-size structural parts (maximum processing range: 3000mm long × 1500mm wide × 1000mm high), it is suitable for heavy equipment frames, large fixture bases, and other requirements. Equipped with five large CNC machining centers and two gantry milling machines, batch orders (100+ pieces) can be produced simultaneously across multiple machines, shortening delivery cycles by 20%-25% compared to the industry average. Standardized processes and first-article inspection ensure 99% dimensional consistency in batch production.

II. Core Application Areas

(I) Industrial Manufacturing Fixtures

- Welding Fixtures and Tooling: Customized 4140 alloy steel welding fixture positioning blocks and clamping arms ensure high strength, preventing workpiece deflection during welding, and offer a positioning accuracy of ±0.003mm, making them suitable for welding automotive bodies and structural parts of construction machinery. - Machining Fixtures: We produce Q235 carbon steel fixture bases and 4340 alloy steel precision chucks. The bases are highly rigid (deflection ≤ 0.03mm/m) and the chucks offer a clamping force of up to 50kN, suitable for high-load machining of shaft and disc components.

(II) Heavy Equipment Structural Parts

- Engineering Machinery Components: We produce 4340 alloy steel excavator booms and 4140 alloy steel crane boom connectors. These components offer a tensile strength of ≥900MPa and can withstand long-term heavy loads (a single component can support 50-200t).

- Machine Tool Structural Parts: We produce Q235 carbon steel machine tool beds and 4140 alloy steel guide rails and sliders. The bed is aged to eliminate internal stress, and the guide rail parallelism is ≤0.004mm/1000mm, ensuring stable machining accuracy.

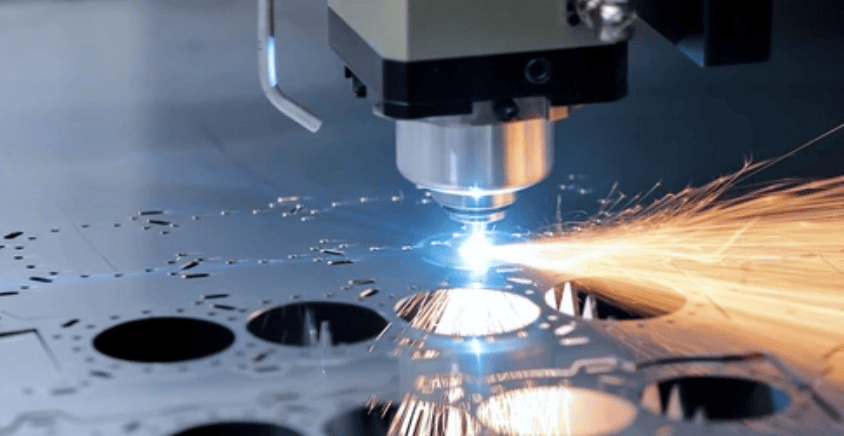

(III) Energy and Mining Equipment

- Wind Turbine Equipment Components: Customized 4140 alloy steel wind turbine flanges and Q235 carbon steel tower connection brackets. Flange bolt hole tolerances are ±0.005mm, suitable for high-altitude, heavy-load operation of wind turbine equipment.

- Mining Machinery Parts: Processing of 4340 alloy steel coal mill scrapers and crusher tooth plates. Surface hardening results in a hardness of HRC52-55, offering excellent wear resistance and suitability for harsh mining conditions.

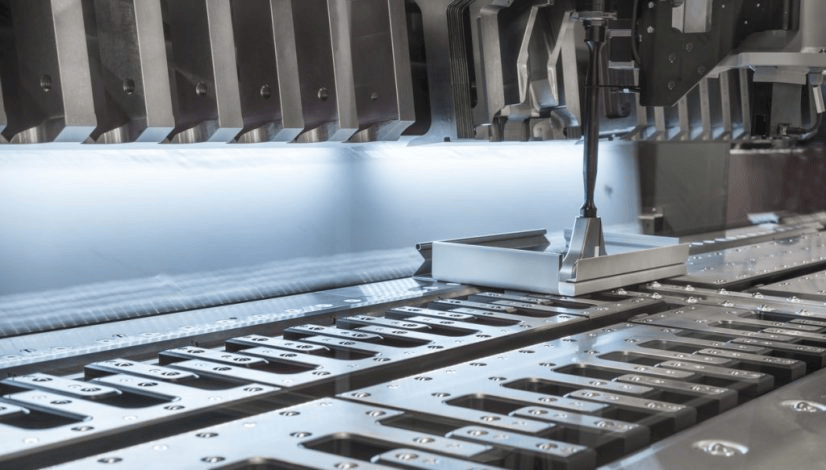

(IV) Molds and Tooling

- Mold Bases and Guide Pins: Production of 4140 alloy steel mold bases and 4340 alloy steel guide pins. Base flatness is ≤0.005mm, and guide pin coaxiality is ≤0.002mm. Suitable for large stamping and injection molds.

- Tooling Platforms: Customized Q235 carbon steel welded tooling platforms with surface milling accuracy Ra ≤0.8μm and T-slot tolerances of ±0.01mm, suitable for flexible clamping of a wide variety of workpieces.

III. Core Technology Support

- Large-Scale, High-Precision Machining Equipment: Equipped with a Taiwan Xiehong CNC-2016 gantry milling machine (travel 2000×1600×800mm) and a German DMG DMF 2600 vertical machining center, the machine boasts a spindle torque of up to 120N·m, enabling high-volume machining of high-strength alloy steels such as 4340. The equipment utilizes a linear scale closed-loop control system with a positioning accuracy of ±0.002mm, ensuring the machining precision of large-scale structural components.

- Specialized Tooling and Process Systems: Utilizing Swedish Sandvik WC-Co carbide tools (for alloy steels) and Japanese Kyocera metal ceramic tools (for carbon steels), coupled with a high-pressure cooling system (80 bar), these tools address tool sticking in alloy steel machining and chip breaking difficulties in carbon steel machining. For deep-cavity structural components, a layered milling process is employed, with each layer cutting to a depth of 0.2-0.5mm, ensuring cavity wall verticality ≤0.004mm. - Heat Treatment and Quality Control: We collaborate with professional heat treatment manufacturers to provide quenching and tempering, quenching, and carburizing services. The hardness of 4140 steel after quenching can reach HB220-260, and the hardness of 4340 steel after quenching can reach HRC45-50. Quality inspection utilizes a three-dimensional coordinate measuring machine (accuracy ±0.001mm), tensile testing machines, and impact testing machines to thoroughly inspect the dimensions and mechanical properties of structural components to ensure they meet high-load standards.

- Fixture Design and Simulation Capabilities: We have a professional fixture design team that can design fixture structures based on customer workpiece drawings (2D/3D). We use UG and AutoCAD software for modeling and ANSYS for stress simulation analysis to optimize the fixture's load-bearing structure, avoid damage caused by localized stress concentration, and maximize fixture life.

Fourth, Frequently Asked Questions (FAQs)

- Q: Besides 4140, 4340, and Q235, what other carbon steel/alloy steel grades can be machined? What are the differences in the applications of the different grades?

A: We can also process 20CrMnTi (carburizing steel, suitable for wear-resistant fixtures), 45# steel (medium carbon steel, suitable for general structural parts), and Q355B (low-alloy high-strength steel, suitable for large brackets). 4140/4340 steel is designed for high-load, high-precision applications; Q235/Q355B steel is designed for low-cost, large-sized structural parts; and 20CrMnTi steel is designed for wear-resistant transmission components.

- Q: What is the machining accuracy of large-sized structural parts? What is the maximum machining weight limit?

A: For structural parts ≤3000mm in length, the dimensional tolerance is ±0.01-±0.02mm, and the flatness is ≤0.008mm/1000mm. The maximum machining weight limit is 5 tons. We can process parts weighing over 5 tons using segmented machining and precision splicing technology, with a flatness of ≤0.01mm at the spliced joints.

- Q: Does heat treatment affect the dimensional accuracy of the part? How can we ensure assembly requirements after heat treatment?

A: Before heat treatment, a 0.1-0.3mm machining allowance is reserved. After heat treatment, fine machining is performed to ensure that the final dimensional tolerances meet the required standards. For example, after heat treatment, the positioning surface of a 4140 fixture can be finely milled to restore flatness to ≤0.003mm, without affecting assembly accuracy.

- Q: What is the design and machining cycle for a custom high-load fixture? Can you provide design optimization suggestions?

A: Simple fixtures (such as single-station positioning fixtures) have a turnaround time of 7-10 days; complex fixtures (such as multi-station welding fixtures) have a turnaround time of 15-20 days. We can provide design optimization suggestions, such as adjusting the fixture clamping force based on the workpiece material and optimizing the positioning point distribution to reduce stress concentration, thereby reducing fixture manufacturing costs and wear and tear.

- Q: How can costs be controlled when mass-producing high-load structural parts? Is there a minimum order quantity (MOQ)?

A: Unit costs are reduced through standardized processes, optimized tool life, and parallel production on multiple machines. The larger the batch size, the more significant the cost advantage. There is no strict minimum order quantity requirement. Small batches (1-10 pieces) can be customized, and large batches (100+ pieces) can provide a 5%-10% price discount, which can be negotiated based on the order quantity.