3C Electronic Magnesium Alloy Case CNC Service - Providing Lightweight Parts with High Rigidity, Impact Resistance, and Electromagnetic Shielding

- Overview

- Related Products

I. Core Service Advantages

- Extremely lightweight, meeting the portability needs of 3C products: Utilizing lightweight magnesium alloys such as AZ31B and AZ91D, with a density of only 1.7-1.8g/cm³, this is 33% lighter than aluminum alloy cases and 75% lighter than stainless steel cases. Through CNC precision hollowing and thin-wall processing (minimum wall thickness 0.8mm), the weight of 3C products can be reduced by 15%-20%. For example, a 15-inch laptop case can be reduced from 800g of traditional aluminum alloy to under 550g, improving portability.

- High Rigidity + Impact Resistance Ensures Product Durability: After undergoing "solid solution + aging" strengthening treatment, the magnesium alloy case achieves a flexural strength of 280-350MPa and an elastic modulus of 45GPa, making it over four times more rigid than plastic cases. The case passed a drop test (1.2m drop to concrete) with no cracking or deformation. Its excellent impact resistance (impact energy ≥ 22J) effectively protects internal electronic components and reduces the risk of accidental damage to 3C products.

- Natural electromagnetic shielding safeguards signal security: Magnesium alloy, a conductive metal, boasts an electromagnetic shielding effectiveness (SE) of 30-50dB, effectively blocking external electromagnetic interference (such as mobile phone and WiFi signals from interfering with the device's internal chips) while preventing the leakage of internal electromagnetic radiation. This complies with 3C product EMC (electromagnetic compatibility) standards (such as EN 55032) and is suitable for the high-frequency signal transmission requirements of the 5G era.

- Precision shape control and attractive appearance align with 3C design trends: Five-axis CNC machining achieves a positioning accuracy of ±0.002mm, enabling the creation of complex exterior features such as curves, curved edges, and gradient colors, with a surface finish of Ra ≤ 0.2μm. Supports diverse surface treatments such as micro-arc oxidation, PVD coating, sandblasting, and brushing, such as matte black sandblasted shells and rose gold PVD-coated middle frames, meeting the "lightweight and beautiful" design requirements of 3C products.

II. Core Application Areas

(I) Smartphones and Tablets

- Mobile Phone Middle Frames and Back Covers: Processing of AZ31B magnesium alloy integrated middle frames with thin walls of 0.8-1.2mm, 25% lighter than aluminum alloy middle frames, while high rigidity ensures the body is not prone to bending; Customized AZ91D magnesium alloy back covers support wireless charging (magnesium alloy does not shield magnetic fields), and surface micro-arc oxidation treatment improves wear resistance, suitable for high-end flagship models.

- Tablet Cases: Producing lightweight magnesium alloy tablet cases weighing ≤100g (11-inch tablets). The impact-resistant structure design can withstand daily drops, and the electromagnetic shielding properties prevent interference with tablet signal reception.

(II) Laptop Computers

- Laptop Cases and Palm Rests: We manufacture AZ91D magnesium alloy laptop cases with hollowed-out heat dissipation holes (CNC precision milling) to improve heat dissipation efficiency. The highly rigid structure supports the internal motherboard and battery, preventing deformation from squeezing. We also customize magnesium alloy palm rests with a brushed finish for a delicate touch and an electromagnetic shielding efficiency exceeding 40dB, preventing interference with keyboard signals.

- Gaming Laptop Cases: We manufacture high-performance magnesium alloy cases for gaming laptops. Ribbed structural design improves rigidity (bending strength ≥ 320MPa) while lightweight design reduces overall weight (30% lighter than plastic cases), meeting the "high performance + portability" requirements of gaming laptops.

- Smart Wearables and Gaming Devices

- Smart Watch Cases: We customize AZ31B magnesium alloy smart watch cases, weighing ≤20g. PVD black plating enhances the look and feel. Impact resistance ensures damage during daily wear, and electromagnetic shielding properties prevent interference with Bluetooth and GPS signals. - Gaming Peripheral Cases: This machine processes magnesium alloy mechanical keyboard and mouse cases. The high-rigidity structure reduces case resonance when keys are pressed, while the lightweight design enhances portability. The sandblasted matte finish is anti-slip and anti-fingerprint, making it ideal for gaming scenarios.

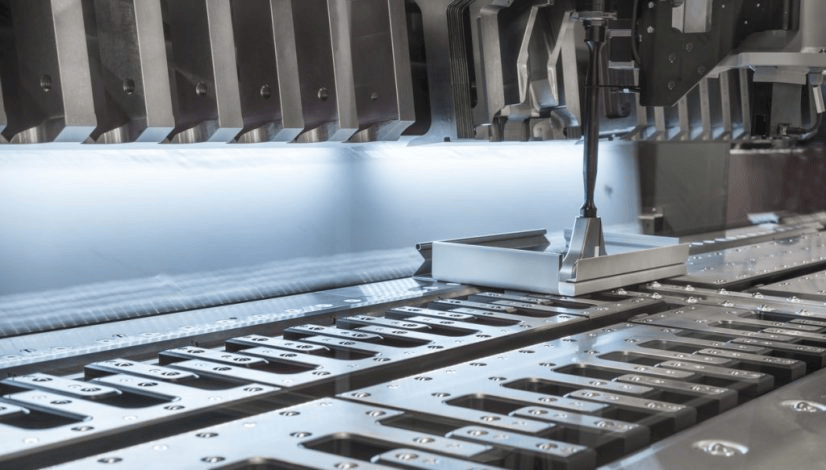

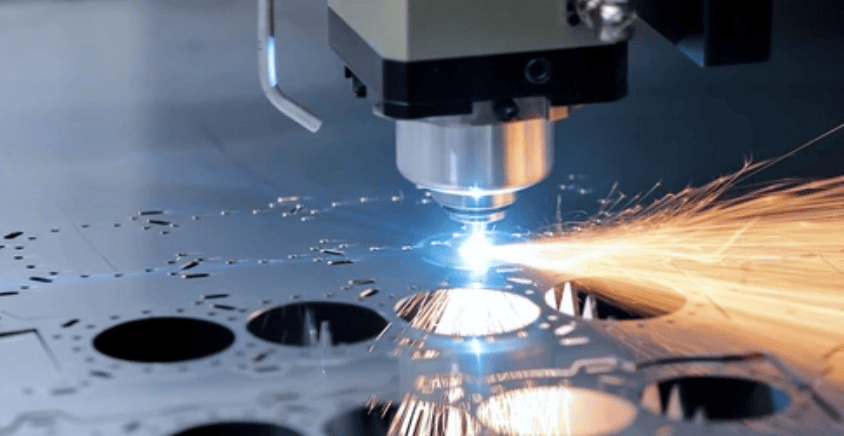

III. Core Technology Support

- 3C-Specific CNC Processing Equipment: Equipped with a Japanese FANUC α-T21iFb precision lathe and a German DMG DMU 35 five-axis machining center, the machine boasts a maximum spindle speed of 18,000 rpm and a rapid traverse speed of 60 m/min. This machine supports precision machining of complex curved surfaces, micropores (minimum diameter 0.5 mm), and narrow slots (minimum width 0.3 mm) for 3C cases, ensuring dimensional tolerances within ±0.002 mm. - Magnesium Alloy Anti-Oxidation Processing: Argon inert gas (purity ≥99.99%) is used throughout the entire machining process to prevent oxidation and discoloration on the magnesium alloy housing surface. Dedicated carbide tools (TiAlN coating) are used in conjunction with cryogenic cutting (cooling temperature 8-12°C) to minimize thermal deformation during machining and ensure dimensional stability of thin-walled housings.

- Diversified Surface Treatment Systems: We offer mainstream surface treatments for 3C electronics, including micro-arc oxidation (film thickness 8-15μm, hardness HV500-600, wear and scratch resistance), PVD coating (film thickness 0.5-3μm, colors available in rose gold and space gray), sandblasting (80-320 grit, matte finish), and brushing (straight and random grain, texture consistency ≤ΔE1.5). All processes comply with RoHS environmental standards. - 3C Industry Quality Inspection Standards: After processing, dimensions are inspected using a three-dimensional coordinate measuring machine (accuracy ±0.0005mm); a drop test (1.2m height, one drop on each of the six surfaces) verifies impact resistance; an electromagnetic shielding test (according to GB/T 17626.3) ensures shielding effectiveness meets standards; and a 20x magnifying glass is used for appearance inspection to check for scratches and dents. The pass rate is over 99.8%, meeting 3C product factory standards.

Fourth, Frequently Asked Questions (FAQs)

- Q: What are the commonly used magnesium alloy grades for 3C electronic magnesium alloy casings? What are the differences?

A: AZ31B (excellent plasticity, suitable for complex curved casings such as mobile phone midframes) and AZ91D (high strength, suitable for load-bearing components such as laptop bottom covers) are commonly used. AZ31B focuses on formability and lightweighting, while AZ91D emphasizes rigidity and impact resistance. The appropriate grade can be selected based on product functional requirements.

- Q: What are the machining accuracy and dimensional changes of magnesium alloy casings after surface treatment?

A: The machining dimensional tolerance is ±0.002-±0.003mm, with a flatness of ≤0.003mm/100mm. A 0.005-0.01mm margin is allowed before surface treatment, and the dimensional tolerance after treatment is ≤±0.002mm. This does not affect the assembly accuracy with the screen or motherboard.

- Q: Does the electromagnetic shielding effectiveness of magnesium alloy casings meet the requirements of 5G products?

A: Yes! Magnesium alloy casings have an electromagnetic shielding effectiveness of 30-50dB, far exceeding the EMC standard requirement of 5G products (≥20dB). They can effectively block 5G high-frequency signal interference without affecting the device's own signal transmission and reception, making them compatible with 5G mobile phones, laptops, and other products.

- Q: What is the delivery lead time for magnesium alloy casings for 3C electronics? Are there any advantages to placing bulk orders?

A: Small batch samples (1-10 pieces) have a lead time of 5-7 days. Large orders (1,000+ pieces) are produced in parallel on multiple machines with a lead time of 7-10 days. The larger the batch, the lower the unit cost. We offer a 5%-8% price discount, which is negotiable.

- Q: Can you provide suggestions for optimizing the housing design? For example, how can we improve rigidity while maintaining lightweight?

A: Yes! Our professional design team can perform topology optimization based on the 3D model. By adding stiffeners, optimizing the hollow structure (such as honeycomb hollowing), and adjusting the wall thickness distribution, we can improve housing rigidity while maintaining lightweight, achieving an average 15%-20% increase in bending strength.

| Processing | CNC Machining Services: Cnc Milling, Cnc Turning, Laser Cutting, Drilling, Bending, Spinning, Wire Cutting, Stamping, Edm, 3-Axis,4-Axis, 5-Axis Machining, Swiss Machine Tool Machining; Comprehensive Machining Services: Powder Metallurgy, Sheet Metal Manufacturing, Stamping, Die Casting, 3d Printing, Injection Molding, Rapid Prototyping, Molds, Etc.; Multi-Process Machining |

| Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Precision Tolerance | ±0.001mm~±0.005mm Specific products can meet customer reguirements. |

| Surface Roughness | Min Ra 0.1~3.2 |

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, Pvd Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder |

| Coated,Sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. | |

| Production volume | Low to Medium Volume, Prototype, and Batch Production |

| Processing Method | Custom According to Provided CAD Drawings |

| Lead Time | Short lead Time, Typically 1-4 Weeks |

| Quality Control | Strict Quality Assurance and Inspection Processes |

| Packaging | Secure Packaging to Prevent Damage During Transit |

| Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

| 1-Piece minimum order | Ability to Provide Samples Before Mass Production |